To check if your truck bed is still structurally sound, inspect for cracks, deformations, and signs of rust or corrosion, especially around welds and joints. Look for water stains, mold, or flaking paint, which indicate water damage. Tap metal surfaces to detect hollow spots or weakness and examine supports and the frame for signs of bending or shifting. Regularly monitor for uneven settlement or warping. If you want to guarantee safety, the next steps will guide you further.

Key Takeaways

- Inspect for visible cracks, deformations, or signs of rust and corrosion on metal surfaces and welds.

- Check for uneven gaps, misalignments, or warping that indicate shifting or settlement.

- Tap metal components to detect hollow spots or internal rust that weaken the structure.

- Examine support joints, bolts, and welds for cracks, corrosion, or looseness.

- Use a level or straightedge to identify dips, tilts, or uneven panels suggesting compromised integrity.

Visual Inspection for Cracks and Deformations

When conducting a visual inspection for cracks and deformations in a truck bed, it is vital to systematically examine all structural walls, beams, and supports. Look closely for any visible cracks, especially around welds, joints, and load-bearing areas. Pay attention to any signs of deformation, such as bending, warping, or buckling of metal panels. Check for uneven gaps or misalignments that could indicate shifting or settlement. Use good lighting to reveal fine cracks that might be hidden in shadowed areas. Note any fresh or dark cracks, which could suggest recent movement. Remember, even small cracks can compromise structural integrity over time. Document your findings accurately, focusing on the location, size, and nature of any cracks or deformations. Additionally, understanding the principles of navigation and mapping can help identify hidden issues that are not immediately visible during a basic visual check.

Checking for Water Damage and Rust

Checking for water damage and rust involves carefully examining all metal and wooden surfaces for signs of moisture intrusion and corrosion. Look for discoloration, stains, or mold on wood, which indicate past or ongoing water exposure. On metal surfaces, inspect for rust spots, flaking paint, or bubbling coatings, as these signal corrosion. Pay close attention to seams, joints, and corners where moisture can accumulate. Use a flashlight to identify hidden rust or water stains beneath the surface. Tap on metal components — a dull sound may suggest internal rust or weakness. Also, check for warped or swollen wooden parts, which can result from water damage. Be aware that water intrusion can sometimes be subtle but damaging over time. Addressing these issues early helps prevent further deterioration and maintains your truck bed’s structural integrity.

Examining Structural Joints and Connections

Start by carefully inspecting the connections for any cracks, gaps, or misalignments. Check that all bolts, welds, and fasteners are secure and properly tightened, as loose or broken securing methods can compromise the structure. Look for signs of corrosion or damage around joints, which may indicate weakened areas that need attention. Evaluating the contrast ratio can also help determine if the structural integrity affects the overall performance.

Visual Connection Inspection

A thorough visual connection inspection is essential for identifying potential issues in structural joints and connections that could compromise the overall integrity of a truck bed. Begin by examining welds, bolts, and rivets for signs of cracking, corrosion, or looseness. Look closely at areas where metal parts meet—any gaps, deformation, or rust may indicate weakening. Check for missing fasteners or signs of fatigue like hairline cracks or stress marks. Pay attention to connection points around mounting brackets, crossmembers, and supports, ensuring they’re securely attached and free from damage. Also, verify that no components are misaligned or shifted, which could signal underlying stress or settling. Conducting a visual connection inspection helps detect early signs of deterioration before they lead to major structural failures.

Tightness and Securing Methods

Ensuring that structural joints and connections are properly secured is essential for maintaining the integrity of a truck bed. You should check for loose bolts, nuts, and welds, as these can compromise stability. Use a torque wrench to verify fastener tightness, and look for any signs of movement or gaps at joints. Regularly inspect connection points for corrosion or wear that could weaken the structure. Tightening or replacing compromised fasteners prevents future issues. Here’s a quick reference:

| Connection Type | Inspection Tip | Action Needed |

|---|---|---|

| Bolted Joints | Check for looseness or rust | Tighten or replace fasteners |

| Welded Joints | Look for cracks or separation | Re-weld if necessary |

| Riveted Connections | Ensure rivets are intact and flush | Repair or reinforce as needed |

Additionally, understanding the structural integrity of your truck bed helps prevent costly repairs and ensures safety.

Signs of Corrosion or Damage

Have you ever noticed corrosion or damage around your truck bed’s structural joints and connections? These areas are critical for maintaining overall integrity. Look for rust or discoloration where metal parts connect, as these signs indicate corrosion that could weaken the structure. Check for loose or bent bolts, rivets, or welds, which suggest compromised connections. Cracks or deformation near joints may reveal stress or fatigue. Water stains, mold, or efflorescence around these points also signal moisture intrusion that accelerates deterioration. Regular inspections can help identify structural vulnerabilities early before they become serious problems. If you find any of these signs, it’s essential to evaluate whether repairs are needed. Addressing corrosion early can prevent more severe damage, ensuring your truck bed remains safe, sturdy, and reliable for the long haul.

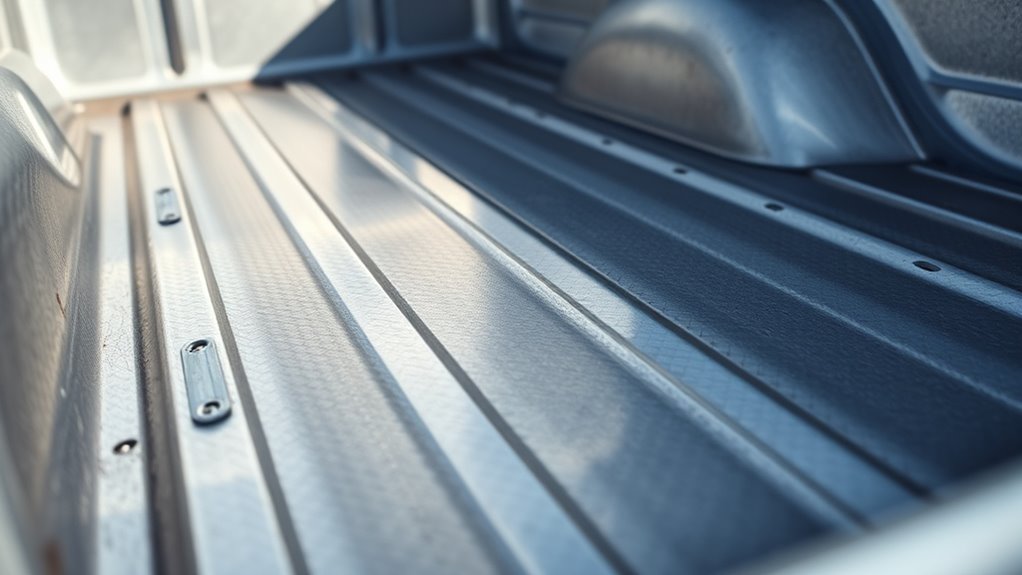

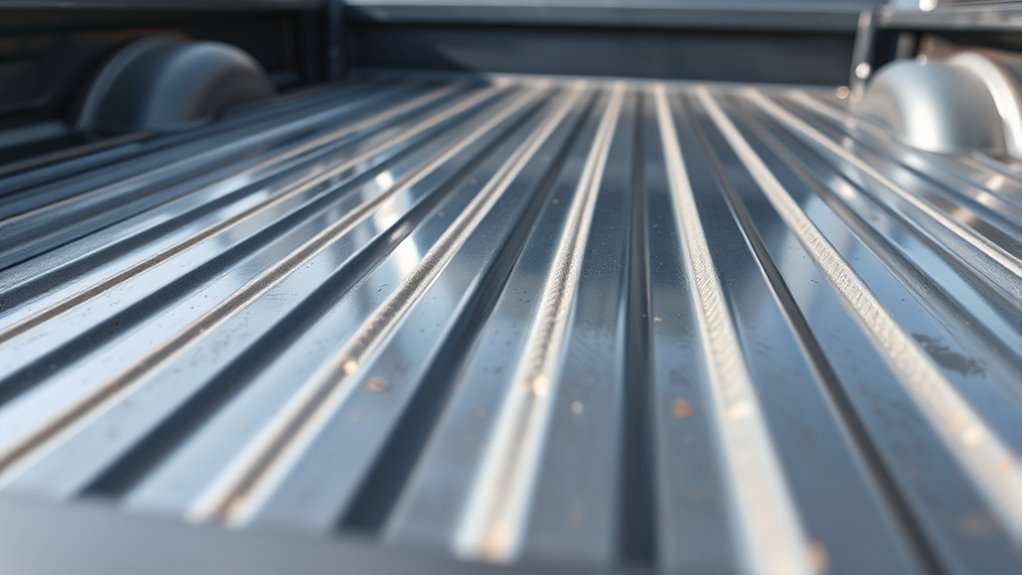

Assessing the Integrity of the Bed Floor

Start by visually inspecting the bed floor for cracks, rust, or other signs of damage that could jeopardize its strength. Check the support beams underneath to make certain they’re intact and not showing signs of bending or corrosion. Address any issues promptly to maintain the bed’s overall integrity and safety. Additionally, consider nanotechnology-based coatings that can help prevent rust and corrosion, extending the lifespan of your truck bed.

Visual Crack Inspection

How can you quickly determine the structural integrity of your truck bed floor? The key is a thorough visual crack inspection. Carefully examine the entire surface for any signs of cracks or fractures, especially near the edges and seams. Look for:

- Fine or wide cracks that could indicate stress or fatigue

- Cracks that run across the bed, suggesting deformation

- Cracks around welds or joints, which may weaken connections

Pay close attention to areas that are frequently loaded or exposed to heavy impacts. Small cracks might seem minor but can expand over time, compromising the bed’s strength. If you notice any of these signs, it’s time to contemplate a more detailed inspection or professional evaluation to ensure your truck bed remains safe and durable.

Structural Support Checks

Inspecting the structural supports of your truck bed floor is vital for maintaining its strength and safety. Start by examining the bed’s underside for visible signs of rust, corrosion, or bent supports. Look closely at the crossmembers and side rails for cracks, warping, or deformation, which can weaken the overall structure. Check all welds and joints to guarantee they remain intact and secure. Tap lightly on supports to listen for hollow or rattling sounds indicating internal damage or detachment. Pay attention to any unevenness or sagging, which signals compromised support. If you notice rust or damage, document it and consider professional assessment. Regular support checks help prevent costly repairs and keep your truck bed safe for heavy loads. Incorporating sizing and load‑planning tools can assist in understanding weight distribution and load limits to prevent future stress on the bed’s supports.

Evaluating Metal Components for Corrosion

Evaluating metal components for corrosion is a critical step in ensuring structural integrity. You need to carefully examine all metal parts, including beams, brackets, and fasteners, for signs of rust or deterioration. Look for areas where corrosion might be hiding, such as hidden crevices or underneath paint. Focus on these key indicators:

- Visible rust patches or flaky surface corrosion

- Discoloration or pitting on metal surfaces

- Structural weakening or thinning of metal parts

Addressing corrosion early can prevent costly repairs or failure. Use a flashlight and a mirror to inspect hard-to-see spots, and tap suspicious areas gently with a tool to check for hollowness or weakness. Regular inspections help maintain your truck bed’s safety and longevity.

Monitoring for Uneven Settlement or Warping

Monitoring for uneven settlement or warping is essential to maintaining the structural integrity of your truck bed. Regularly check for visible signs like dips, tilts, or misaligned panels. Use a straightedge or level to verify flatness across the surface, especially after heavy loads or rough terrain. Pay attention to any gaps between panels or unusual creases. If you notice unevenness, inspect underlying supports and frame connections. Being aware of modern maintenance techniques can also help detect early issues before major repairs are needed.

Utilizing Non-Destructive Testing Methods

Utilizing non-destructive testing (NDT) methods allows you to assess the internal condition of your truck bed’s structural components without causing damage. These techniques help identify hidden issues like internal cracks, corrosion, or material thinning that aren’t visible to the naked eye. By using NDT, you can make informed decisions about repairs or maintenance before problems worsen. Incorporating expert voice actors into your inspection process can improve communication and understanding of complex testing results.

Inspecting the Frame and Support Structures

Inspecting the frame and support structures is essential to guarantee your truck bed’s integrity. Carefully examine for cracks, rust, or deformation on beams, crossmembers, and supports. Look for signs of water damage, such as stains or mold, which weaken metal and wood. Check joints and welds for separation or corrosion, ensuring they remain secure. Use a flashlight to spot hidden issues and tap lightly to detect hollow or weak spots. Regular inspections help identify early problems before they worsen.

| Area | What to Look For | Possible Issue |

|---|---|---|

| Beams & Crossmembers | Cracks, rust, deformation | Structural weakness, corrosion |

| Joints & Welds | Separation, rust | Connection failure |

| Supports & Mounts | Water stains, rust | Material degradation |

| Frame Base | Uneven settling, cracks | Foundation instability |

| Bolts & Fasteners | Loose, rusted, missing | Reduced support strength |

Reviewing Maintenance and Repair History

Reviewing the maintenance and repair history provides critical insights into the truck bed’s structural condition. It helps you identify recurring issues or previous damage that could compromise its integrity. By examining records, you can see if there have been repeated repairs or unresolved problems, indicating underlying weaknesses. This review also confirms whether past repairs were effective or if further work might be needed. Additionally, understanding the history allows you to compare the current condition against original specifications and standards. Recognizing patterns of wear or damage can guide your inspection and decision-making process. To get a clear picture, focus on these key points:

Reviewing repair history reveals underlying issues and guides informed decisions about truck bed integrity.

- Past repairs and their outcomes

- Frequency of maintenance and repairs

- Signs of unresolved or recurring issues

Frequently Asked Questions

How Can I Detect Internal Metal Fatigue Without Disassembly?

You can detect internal metal fatigue without disassembly by using non-destructive testing methods like ultrasonic or magnetic particle testing. These techniques assess internal integrity and surface flaws without damaging the structure. Look for signs of corrosion or deformation that could indicate stress buildup. Regular inspections, especially in high-stress areas, help catch fatigue early before it results in failure, keeping your truck bed safe and reliable.

What Signs Indicate Weakness in the Truck Bed’s Load-Bearing Capacity?

You notice cracks or deformations in the truck bed’s beams or supports, which signal weakened load capacity. For example, if you see rust around welds or bends in the metal, it indicates material degradation. Uneven settling or tilting also suggests compromised structural integrity. Regularly inspecting joints, connections, and signs of rust or fatigue helps you catch issues early, preventing potential failure under heavy loads.

Are There Specific Environmental Factors That Accelerate Structural Deterioration?

Environmental factors like moisture, salt, and temperature fluctuations can speed up your truck bed’s deterioration. You might notice rust, corrosion, or cracking developing faster if exposed to humid or salty conditions regularly. Extreme temperature changes cause expansion and contraction, weakening materials over time. To protect your truck bed, keep it dry, wash off salt after winter, and park in shaded areas when possible. Regular inspections help catch damage early before it worsens.

How Often Should I Perform a Structural Integrity Assessment?

You should schedule structural assessments systematically, at least annually, to stay ahead of potential problems. Regular reviews reveal deteriorating damage and dangerous deformations, keeping your truck bed’s strength steadfast. More frequent inspections are wise if you experience severe environmental exposure, heavy hauling, or notice unusual noises or movements. Consistent checks create a clear, current condition, ensuring safety, stability, and long-lasting durability for your truck bed over time.

Can Minor Visible Damage Lead to Major Structural Failures Later?

Yes, minor visible damage can lead to major structural failures later if left unaddressed. Cracks, rust, or water stains might seem small, but they can indicate deeper issues like material degradation or internal damage. Over time, these problems can weaken key components, causing potential failure under load. Regular inspections and timely repairs guarantee that small issues don’t escalate, keeping your truck bed safe and durable.

Conclusion

To keep your truck bed in top shape, stay vigilant and don’t ignore small issues—they can snowball into bigger problems. Regular checks ensure you catch trouble before it’s too late, saving you time and money. Remember, an ounce of prevention is worth a pound of cure, so make inspection a habit. When in doubt, consult a professional—better safe than sorry, after all. Your truck’s longevity depends on how well you care for it.