To prevent tools from bouncing out of your open truck bed, securely fasten them using reinforced, lockable tool boxes with weatherproofing. Organize tools with dividers or foam padding to keep items stable and absorb shocks. Distribute weight evenly, placing heavier items low and centered, and use tie-down straps to stabilize the load. Regularly inspect hardware to guarantee everything stays tight and secure. Keep exploring to learn more about safeguarding your tools during transit.

Key Takeaways

- Use secure mounting systems and lockable tool boxes to prevent movement and theft during transit.

- Incorporate padding, foam inserts, and dividers to absorb shocks and keep tools in place.

- Distribute heavy tools evenly, placing them low and centered to maintain vehicle stability.

- Install vibration-damping pads and secure latches to minimize bouncing caused by road vibrations.

- Regularly inspect and tighten mounting hardware and restraints to ensure ongoing tool security.

Use Secure Mounting Systems for Tool Storage

Using secure mounting systems is essential to keep tools stable during transit. You want your tools to stay put, even during sudden stops or sharp turns. Reinforced latch mechanisms on truck bed tool boxes prevent tools from shifting or falling out when the vehicle accelerates or brakes quickly. Mounting kits secured to bed stake pockets or tapped holes within the frame provide solid anchoring points, ensuring stability. Properly installed, these systems resist vibration and impact, reducing the risk of movement. Additionally, full-length seal gaskets and tamper-proof hinges keep tools locked inside when the tailgate is closed. Selecting high-quality mounting options and securing your storage properly helps prevent damage and theft, ensuring your tools remain safe on the road.

Incorporate Proper Tool Organization and Dividers

Effective tool organization is key to preventing shifting and damage during transit. When you use proper dividers, trays, and foam inserts, tools stay in place and reduce movement. Zoning tools by type—like hand tools, power tools, and hardware—makes it easier to find what you need and keeps items secure. Removable bags add portability without sacrificing order, preventing delicate tools from bouncing around. Implementing these systems minimizes clutter and helps you quickly identify missing tools after transport. Incorporating tool storage solutions can further enhance organization and security during transit.

Choose Reinforced and Lockable Tool Boxes

Choosing reinforced and lockable tool boxes enhances security and durability, ensuring your tools stay safe during transit. Reinforced materials, like heavy-duty steel or aluminum, resist impacts and harsh weather, preventing damage and theft. Lockable features add an extra layer of security, deterring theft and accidental openings during sudden stops or rough terrain. Look for boxes with tamper-proof locks and reinforced latches that withstand repeated use and vibration. A sturdy, well-built toolbox also helps prevent shifting and bouncing, especially when combined with proper mounting. Investing in high-quality, lockable storage means you won’t have to worry about tools bouncing out or getting stolen, giving you peace of mind whether you’re driving through city streets or rugged off-road trails. Additionally, selecting tool storage with impact-resistant features can further protect your tools from damage during rough rides.

Implement Vibration Damping Measures

You can reduce tool movement by installing vibration-damping pads beneath your storage units, which absorb road shocks and vibrations. Ensuring your latches are secure prevents accidental openings during transit, especially on rough roads. Properly maintaining these measures keeps your tools in place and minimizes bouncing. Additionally, utilizing smart organization systems can optimize space and further secure your tools during transport.

Use Vibration-Damping Pads

Vibration-damping pads play a crucial role in keeping tools secure during transportation by absorbing road shocks and engine vibrations. By placing these pads beneath your toolboxes or storage containers, you reduce the movement caused by rough roads and engine noise. The pads act as shock absorbers, preventing your tools from shifting or bouncing around. They also help minimize vibrations that can loosen latches and mounts over time. Choose high-quality, durable pads made from rubber, foam, or specialized damping materials suited for heavy-duty use. Install them on stable surfaces, ensuring full contact between the pad and the toolbox. Regularly inspect and replace worn or compressed pads to maintain their effectiveness. Using vibration-damping pads enhances stability and considerably lowers the risk of tools bouncing out during transit. Incorporating European cloud innovation principles can inspire the development of advanced damping materials that improve safety and durability in transportation.

Secure Latches Properly

How can you guarantee that your tool latches stay secure during rough rides? Properly securing your latches is key. Always check that latch mechanisms are fully engaged and free of debris. Use reinforced or heavy-duty latches designed to withstand vibrations. Applying lubricant ensures smooth operation and prevents sticking or jamming. Consider adding vibration dampers or padding around latch areas to absorb shocks. Proper training on latch operation reduces accidental openings. Additionally, consulting reliable backup power guidelines can help you stay prepared in case of emergencies. Below is a quick reference:

| Latch Type | Best Practice |

|---|---|

| Standard latch | Ensure full engagement before driving |

| Reinforced latch | Regularly inspect for wear and damage |

| Padlocks or secures | Always lock for extra security |

Secure latches firmly and routinely inspect to prevent tool loss.

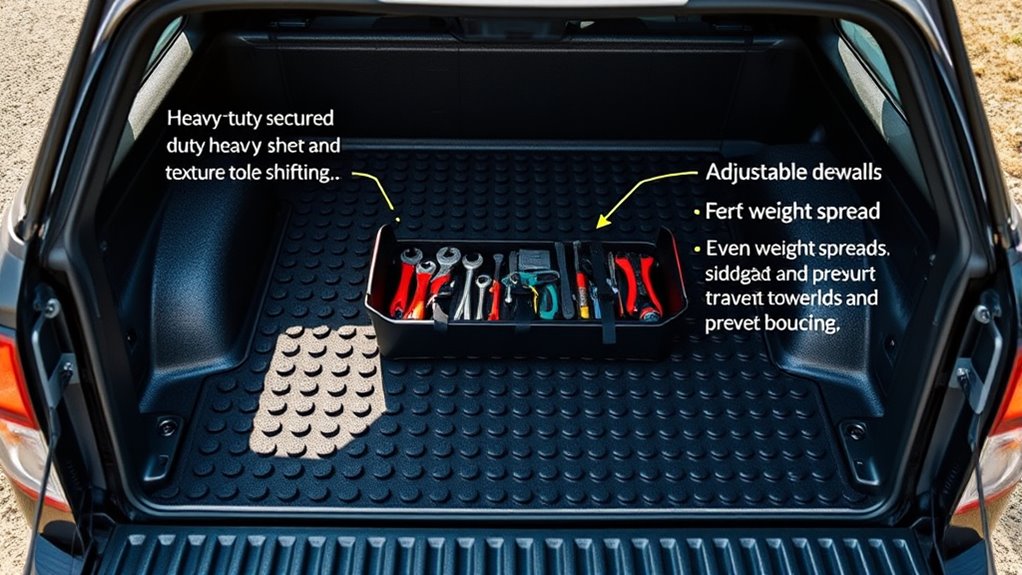

Optimize Load Distribution and Weight Balance

To keep your tools secure, you need to distribute heavy items evenly across the truck bed. Centering your load helps maintain overall stability during transit. Remember to use proper restraints to prevent shifting and guarantee everything stays in place. Additionally, securing your tools with appropriate storage solutions can further reduce the risk of movement or bouncing.

Distribute Heavy Items Evenly

Distributing heavy items evenly in your truck bed is essential for maintaining ideal load balance and ensuring safe driving conditions. When heavy tools or equipment are concentrated on one side, it can cause your truck to sway or become unstable, especially during turns or sudden stops. Place heavier objects toward the front of the bed, near the cab, to help distribute weight evenly across the vehicle. Use load bars or dividers to secure heavy items in position and prevent shifting. Balance lighter items around the heavy ones to maintain a level load. This even distribution minimizes strain on your suspension, improves handling, and reduces the risk of tools bouncing out or damaging your vehicle during transit. Proper weight balance is key to safe, secure transport.

Center Weight for Stability

Centering weight in your truck bed helps improve overall stability by balancing the load across the vehicle. When weight is properly distributed, your truck handles better, and tools stay securely in place. To achieve this, place heavier items toward the center of the bed, just behind the cab, and keep lighter tools near the tailgate. Use the following table to guide your placement:

| Heavy Items | Center of Bed | Light Items |

|---|---|---|

| Power tools, toolboxes | Just behind the cab | Hand tools, safety gear |

| Equipment batteries | Middle of the bed | Small hardware parts |

| Large bulk materials | Near the cab | Loose fasteners |

| Heavy cases or containers | Centered for balance | Small containers |

| Construction gear | Close to the cab | Fragile or loose items |

Proper weight placement keeps your load stable and tools secure. Additionally, ensuring the load is evenly distributed can also prevent tool bouncing and enhance your safety while driving.

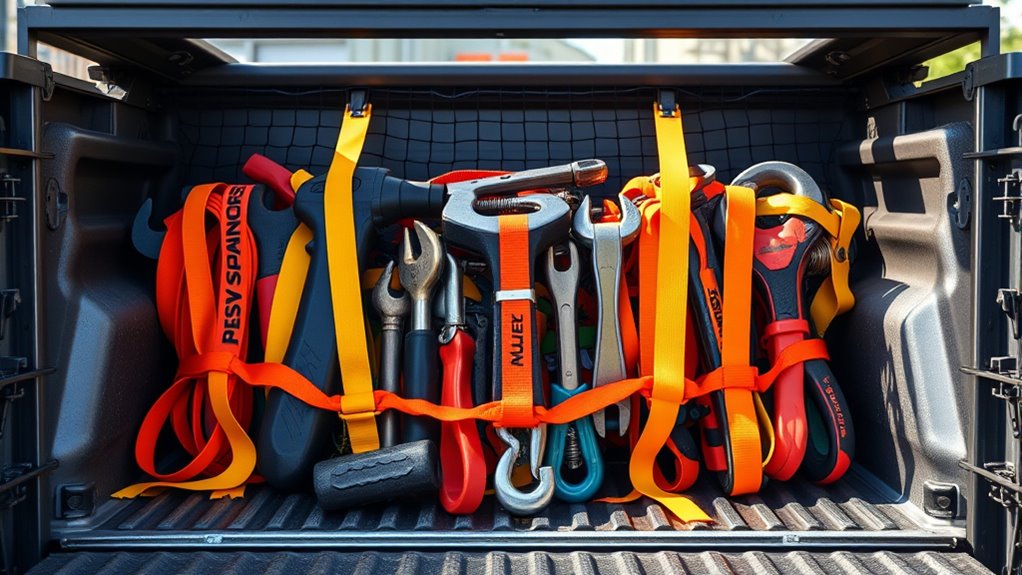

Use Proper Load Restraints

Ensuring proper load restraints is essential for maintaining balance and preventing tools from shifting during transit. You should distribute weight evenly across your truck bed, placing heavier items toward the center and low to the ground. Use tie-down straps, bungee cords, or rope to secure tools and equipment firmly. Properly tension these restraints so they don’t loosen during bumps or quick stops. Consider using load bars or dividers to keep items from sliding side to side. Ensure all restraints are rated for the weight you’re securing. Regularly inspect and tighten straps during your journey. This prevents tools from bouncing around, reduces the risk of items falling out, and maintains vehicle stability, making your trip safer and more efficient. Load distribution is a key factor in optimizing load restraint effectiveness and ensuring safe transportation.

Install Weatherproofing Features to Prevent Water Damage

Installing weatherproofing features on your truck bed tools is essential to protect them from water damage and corrosion. Proper weatherproofing guarantees your tools stay dry, secure, and ready for use. Here are four effective methods:

- Use full-length seal gaskets around toolbox lids to prevent water intrusion during rain or washings.

- Install drainable systems at the bottom of toolboxes with support runners to allow water to escape, reducing internal moisture.

- Choose watertight construction with tight seals and corrosion-resistant materials for long-lasting durability.

- Apply weather seals along edges and joints to maintain integrity during heavy rain and pressure.

- Incorporate ventilation considerations to facilitate airflow and reduce internal humidity, further protecting your tools from moisture buildup.

These measures keep your tools dry, protect against rust, and extend their lifespan, ensuring you’re always prepared for work.

Regularly Inspect and Maintain Mounting Hardware

Regular inspections of your mounting hardware are essential to keep tools secure during transit. Over time, bolts, nuts, and brackets can loosen due to vibrations, impacts, or corrosion. Check all mounting points regularly, ensuring fasteners are tight and free of rust or damage. Look for signs of wear, such as cracks or deformation, that could compromise stability. Replace any worn or corroded hardware immediately to prevent failures. Lubricate moving parts like hinges and latches to maintain smooth operation and reduce the risk of sudden releases. Confirm that brackets and mounts remain properly aligned and securely attached to the truck bed. Routine maintenance guarantees your storage systems stay stable, preventing tools from shifting or bouncing out during transport. Staying proactive keeps your tools secure and extends the lifespan of your mounting hardware.

Utilize Foam Inserts and Padding for Extra Protection

Adding foam inserts and padding to your tool storage helps protect tools from damage caused by vibrations and impacts during transit. Using the right padding can markedly reduce movement and prevent tools from knocking against each other or the walls of your storage. Consider these strategies:

- Customize foam inserts to fit each tool’s shape, ensuring a snug fit.

- Use thick foam pads in high-impact areas to absorb shocks.

- Place rubber or felt padding under heavy tools to minimize vibrations.

- Regularly replace worn or compressed padding to maintain protection.

These measures keep your tools secure and prevent shifting that can cause damage or lead to tools bouncing out of the truck bed. With proper padding, you’ll extend your tools’ lifespan and reduce the risk of loss during transit.

Train Personnel on Proper Loading and Securing Procedures

Proper training guarantees that personnel understand how to load and secure tools correctly, considerably reducing the risk of items shifting or bouncing out during transit. You should emphasize the importance of using appropriate storage systems, like reinforced tool boxes and organized compartments, to keep tools stable. Teach staff to evenly distribute weight and avoid overloading the truck bed, which can cause imbalance. Demonstrate how to properly engage latches, locks, and mounting hardware to prevent accidental openings. Regularly review securing procedures and encourage personnel to inspect tools and mounting points before and after trips. Proper training safeguards everyone is aware of best practices, minimizes mistakes, and promotes consistent safety standards. Well-trained staff are your first line of defense against tool loss and potential accidents on the road.

Frequently Asked Questions

What Are the Best Materials for Durable Truck Bed Tool Boxes?

You should choose durable materials like heavy-duty aluminum, reinforced steel, or high-impact plastic for your truck bed tool box. Aluminum is lightweight, corrosion-resistant, and easy to maintain, while steel offers maximum strength and security. High-impact plastic combines durability with affordability and resistance to weather. These materials withstand harsh conditions, resist rust, and provide long-lasting performance, ensuring your tools stay secure during transit and rough terrain.

How Do I Choose the Right Mounting System for My Truck Bed?

You need to match the mounting system to your truck bed and tools. Think of it like finding a glove that fits perfectly—choose mounts that secure heavy loads with bolts through tapped holes or stake pockets. Use rail-mounted brackets for versatility and wedge-shaped designs to prevent lateral shifts. Make sure the system is sturdy, properly installed, and suited for your specific truck bed to keep everything locked in place during transit.

What Tools Are Recommended for Proper Load Balancing?

You should use load balancers like adjustable tie-down straps, load bars, and weight distribution systems to guarantee proper load balancing. Secure heavy tools with these devices to prevent shifting during transit. Distribute weight evenly across the truck bed, placing heavier items near the cab and lighter ones toward the tailgate. Regularly check and tighten straps, and use foam inserts or dividers to keep tools stable and prevent movement.

How Often Should I Inspect My Tool Storage Setup?

Ever wonder how often you should check your tool storage setup? You should inspect it at least once a month to make sure everything stays secure. Regular checks help identify loose latches, worn seals, or shifting loads early, preventing tool loss or damage. After rough rides or extreme weather, do a quick walk-around to confirm all components are tight and in place. Staying proactive keeps your tools safe and your setup reliable.

Can Weatherproofing Features Fully Prevent Water Damage?

Weatherproofing features considerably reduce water damage but can’t fully prevent it. You should make sure your storage units have full-length seal gaskets, watertight construction, and drainable bottoms to minimize moisture intrusion. Properly maintaining these features, like checking seals and drainage regularly, helps keep water out. However, no system is completely impervious, so combining weatherproofing with proper storage practices offers the best protection against water damage to your tools.

Conclusion

By following these steps, you’ll keep your tools secure and prevent costly accidents. Imagine a construction worker who used reinforced lockable boxes and proper load distribution—his tools stayed put even on rough roads. Regular checks and training ensure everyone knows how to load correctly. With these measures, you’ll confidently tackle jobs, knowing your tools won’t bounce out and cause delays or hazards. Stay proactive, and your equipment stays safe and ready when you need it.