To prevent surface rust under a bed mat or storage box, choose moisture-resistant liners like TPE or UV-resistant materials, and guarantee they fit securely with proper sealing along all edges. Improve drainage by adding channels and sloped surfaces to direct water away, and promote good ventilation to keep moisture off surfaces. Regularly inspect, clean, and dry the area, and consider protective coatings to enhance durability—staying proactive helps keep rust at bay and preserves your setup longer.

Key Takeaways

- Ensure a tight, properly sealed liner with sealant along edges and corners to prevent moisture intrusion.

- Incorporate drainage channels and sloped surfaces to direct water away from storage areas.

- Use moisture-resistant and UV-resistant materials for liners to withstand environmental exposure.

- Maintain unobstructed ventilation routes to promote air circulation and moisture evaporation.

- Conduct regular inspections and clean debris or water buildup promptly to prevent rust formation.

Choosing the Right Moisture-Resistant Liner Materials

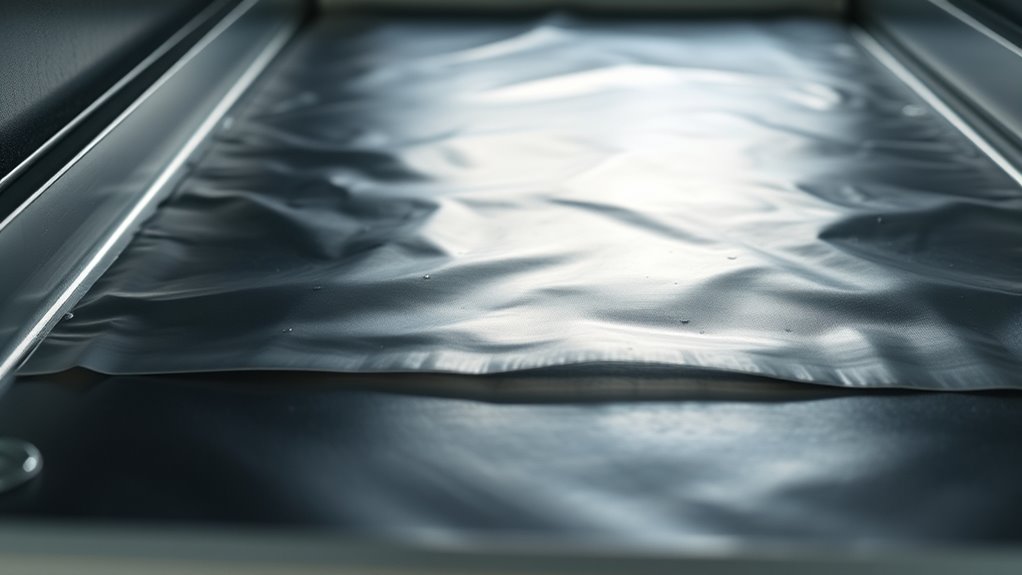

Selecting the right moisture-resistant liner materials is essential for protecting your truck bed from rust. You want materials that block water infiltration and resist deterioration over time. TPE (Thermoplastic Elastomer) mats are a smart choice because they’re flexible, durable, and resist moisture better than traditional rubber. Custom-molded liners with drainage channels help direct water away from the metal surface, reducing rust risks. UV-resistant materials withstand sun exposure without cracking or fading, maintaining their protective qualities. High-quality liners also resist harsh chemicals like gasoline, oils, and cleaning agents that can weaken their barrier. Durability across temperature changes *guarantees* long-lasting protection. Choosing the right material *assures* your truck bed stays dry and rust-free, even under challenging environmental conditions. Incorporating energy-efficient manufacturing processes in liner production can further enhance sustainability and environmental friendliness.

Proper Installation Techniques for a Secure Fit

To guarantee your liner provides maximum protection, you need to measure carefully and cut precisely to fit your truck bed. Proper sealing methods, like applying sealant along edges and corners, keep moisture out and prevent rust. When installation is done correctly, the liner stays secure, and your metal surfaces stay dry and rust-free. Additionally, using appropriate mounting and installation techniques helps ensure the liner remains firmly in place over time.

Precise Measurement and Cutting

Achieving a secure fit begins with accurate measurement and careful cutting of your liner materials. Start by thoroughly measuring your truck bed’s length, width, and depth, noting any irregularities or curves. Use a flexible measuring tape for precision, and double-check your measurements to avoid errors. Transfer these measurements onto your liner material, marking clearly with a marker or chalk. When cutting, use sharp scissors or a utility knife to ensure clean, straight edges. Take your time to follow your markings precisely, avoiding unnecessary gaps or overlaps. Properly measuring and cutting your liner minimizes gaps where moisture can seep in, ensuring a tight, secure fit. Additionally, understanding the importance of precise installation techniques helps prevent issues like surface rust and ensures the liner functions effectively as a moisture barrier. This step is essential for creating an effective barrier against rust and moisture intrusion beneath your bed mat or storage box.

Secure Sealing Methods

Ensuring a secure seal starts with proper installation techniques that eliminate gaps and weak points. Begin by thoroughly cleaning the truck bed surface to remove dirt, debris, and moisture. Carefully position your liner or mat so it fits snugly against all edges and corners. Use high-quality, weather-resistant sealants or adhesive strips designed for automotive use to secure edges and seams, preventing water from seeping underneath. Pay close attention to junction points like corners and seams, applying extra sealant where needed. For added protection, consider sealing around bolts, supports, and edges with waterproof tape or foam. Confirm the liner is pressed firmly against the bed surface, and double-check for gaps. Proper sealing creates a barrier that keeps moisture out and prevents rust formation. Additionally, selecting appropriate sealants formulated for automotive environments can significantly improve the longevity of the seal.

Designing Effective Water Drainage and Management Systems

Effective water drainage starts with designing your system to direct moisture away from vulnerable metal surfaces quickly and efficiently. You want to prevent water from pooling or lingering, which accelerates rust formation. To achieve this, incorporate features like drainage channels, sloped surfaces, and strategic gaps. These elements guide water toward designated exit points, reducing humidity and moisture buildup beneath mats or storage boxes. Consider installing:

Design your system with drainage channels, sloped surfaces, and strategic gaps to quickly direct moisture away from metal surfaces.

- Channels that channel water away from critical areas

- Sloped surfaces that encourage natural runoff

- Gaps or vents that promote air circulation and evaporation

- Proper drainage design to ensure water is effectively diverted and does not accumulate.

Ensuring Adequate Ventilation and Air Circulation

Proper air circulation is essential for preventing moisture buildup beneath bed mats and storage boxes. When airflow is restricted, humidity levels rise, trapping moisture against metal surfaces and speeding up rust formation. To promote ventilation, ensure gaps or vents are present and unobstructed. Consider adding vented panels or mesh screens to create pathways for air movement. Visualize the airflow with this table:

| Area | Airflow Pathway |

|---|---|

| Under the bed mat | Vents or gaps in the mat |

| Edges of storage box | Mesh or perforated panels |

| Corners | Openings for circulation |

| Along the sides | Clear space to allow airflow |

| Near drainage points | Ventilation for moisture escape |

Maintaining these pathways keeps moisture from settling, reduces humidity, and helps prevent rust from forming underneath your bed mat or storage box. Additionally, adequate ventilation can be achieved by regularly checking and cleaning these pathways to ensure they remain unobstructed.

Regular Inspection and Maintenance Routines

You should regularly check your truck bed for any signs of damage or wear, like cracks or shifting liners, to catch issues early. Keep the area clean by removing debris and dirt that can trap moisture and promote rust. By monitoring these factors consistently, you can prevent small problems from turning into costly corrosion.

Visual Inspection Techniques

Have you ever noticed small cracks or shifts in your bed liner that could signal underlying issues? Regular visual inspections are essential to catch early signs of rust risk. Examine seams, edges, and corners where moisture can seep in. Look for:

- Cracks or tears that expose metal surfaces

- Displaced or bubbling liner material

- Accumulated dirt, debris, or water pooling beneath coverings

Pay close attention to areas around fasteners and seams, as these are common entry points for moisture. Use a flashlight to check hidden sections, especially after rain or snow. Address any damage immediately by cleaning and repairing or replacing liners. Conducting seasonal checklists and routine inspections can help maintain the integrity of your truck’s protective layers. Consistent inspections help prevent rust from developing into costly corrosion, keeping your truck protected and extending its lifespan.

Cleaning and Debris Removal

Regular cleaning and debris removal are essential steps in maintaining your truck bed’s resistance to rust. Dirt, leaves, and other debris can trap moisture beneath bed mats or storage boxes, creating a perfect environment for corrosion. You should regularly lift or remove these coverings to inspect the underlying metal surfaces. Use a gentle brush or cloth to wipe away dirt and debris, paying close attention to corners and seams where moisture tends to accumulate. If you notice any trapped water or stubborn grime, clean it with mild soap and water. After cleaning, guarantee the area is thoroughly dry to prevent moisture from lingering. Incorporating routine cleaning into your maintenance schedule helps eliminate potential rust triggers before they can cause damage. Additionally, understanding Free Floating design principles can help ensure your backyard or outdoor space remains free of excessive moisture that could contribute to rust or deterioration.

Monitoring for Early Signs

Consistent inspection of your truck bed helps catch early signs of rust before they develop into serious damage. Regularly check beneath bed mats and storage boxes for discoloration, bubbling paint, or rough patches. Look for moisture buildup, especially in corners or along seams, which can indicate trapped water. Early detection allows you to address issues before they worsen. Incorporating simple maintenance routines can further prevent rust formation and prolong the lifespan of your truck bed.

Cleaning Procedures to Remove Corrosive Substances

Effective removal of corrosive substances like salt, oil, and chemicals is crucial for preventing surface rust. Start by thoroughly cleaning the affected area with a mixture of mild soap and water. Use a soft brush or cloth to scrub away stubborn residues. For salt deposits or hardened grime, consider using a solution of water and vinegar or a commercial rust remover, following the manufacturer’s instructions. Rinse the area completely to eliminate any leftover chemicals, then dry it thoroughly with a clean cloth or compressed air. Avoid leaving moisture behind, as it can accelerate corrosion. Regular cleaning not only removes damaging substances but also helps you spot early signs of rust or damage, allowing for prompt intervention before rust becomes severe.

Protecting Liners From UV Damage and Environmental Factors

Have you considered how prolonged exposure to sunlight and harsh environmental conditions can weaken your truck bed liners? UV rays can cause materials to fade, crack, and lose their protective properties, making moisture penetration more likely. To shield your liners, choose UV-resistant materials designed to withstand sun damage. Regularly applying a UV protectant spray can extend their lifespan and maintain flexibility. Also, consider parking your truck in shaded areas or using a cover to reduce direct sunlight exposure. Additionally, selecting UV-resistant materials or coatings can significantly prevent cracking and deterioration over time. Taking these steps helps preserve your liner’s integrity, reducing the risk of moisture intrusion and subsequent rust formation.

Addressing Chemical Exposure and Contamination Risks

Chemical exposure poses a significant threat to your truck bed liners, especially when fuel, oils, and cleaning agents come into contact with their surfaces. These substances can degrade liner materials, creating cracks and weakening protective barriers. If you don’t clean spills promptly, chemical residues can seep into gaps, accelerating corrosion beneath the liner. Harsh cleaning chemicals may also damage the liner’s integrity if used improperly. To prevent contamination, always wipe up spills immediately and use compatible cleaning products. Regularly inspect the liner for signs of chemical damage or residue buildup. When necessary, replace worn or compromised liners to maintain a sealed barrier. Avoid exposing your liner to prolonged contact with aggressive chemicals, and handle spills with care to preserve its protective function.

Using Secondary Protective Coatings for Enhanced Durability

Adding secondary protective coatings creates extra moisture barriers that can substantially extend your metal’s lifespan. These layers work together with primary liners to block water and contaminants more effectively. When applied correctly, they boost your overall rust prevention strategy without adding much complexity.

Additional Moisture Barriers

Secondary protective coatings serve as an essential layer of defense against moisture intrusion and rust formation. They add an extra barrier that helps prevent water from reaching your metal surfaces, especially in vulnerable spots. Applying these coatings over primary liners or existing rust-proofing enhances durability and extends your protection. You should consider these key benefits:

- Redundancy: Multiple layers reduce the chance of moisture bypassing protection.

- Sealing: They fill small gaps and cracks, preventing water seepage.

- Longevity: Extra coatings withstand environmental stressors, maintaining their barrier over time.

Choosing the right secondary coatings, like specialized rust inhibitors or sealants, ensures your truck bed remains rust-free. Regular reapplication maintains this defense, especially after cleaning or heavy use, keeping metal surfaces protected longer.

Extended Protection Layers

To maximize your truck bed’s resistance to rust, applying extended protection layers with secondary coatings can substantially boost durability. These coatings act as an extra barrier, sealing small gaps and reinforcing existing liners against moisture intrusion. You can choose from specialized paints, sealants, or topcoats designed for metal protection. Proper application guarantees the coatings bond well, providing long-lasting defense. Think of it as adding a second shield over your primary liner, making it harder for water and contaminants to reach the metal. Here’s a visual to help you understand the layers:

| Primary Layer | Secondary Coating | Additional Barrier |

|---|---|---|

| Bed liner material | Protective topcoat | Sealant or paint |

| Moisture-resistant | UV-resistant | Chemical resistant |

| Flexible and durable | Hard and resilient | Extended longevity |

| Installed under bed mats | Applied over liners | Ensures comprehensive coverage |

Best Practices for Sealing Gaps and Edges

Sealing gaps and edges effectively is crucial for preventing moisture intrusion and surface rust. Proper sealing blocks water from seeping into hard-to-reach areas, where it can cause corrosion. To achieve this, ensure all joints, corners, and edges are tightly sealed using high-quality sealants or weatherproof tapes. Pay special attention to areas around fasteners and seams, which are common entry points for moisture. For best results:

- Use flexible, weather-resistant sealants that adapt to movement and temperature changes

- Apply sealant evenly along all edges and joints, avoiding gaps or air pockets

- Regularly inspect and reapply sealant or tape to maintain an impermeable barrier

Consistent maintenance guarantees the integrity of your seal, reducing rust risk and prolonging the lifespan of your truck bed components.

Frequently Asked Questions

How Long Do Moisture-Resistant Liners Typically Last Before Replacement?

Moisture-resistant liners typically last between 5 to 10 years before needing replacement. You should inspect them regularly for signs of wear, cracking, or shifting, especially after extreme weather or heavy use. Proper installation and maintenance can extend their lifespan. If you notice any damage or loss of protective features, replace the liners promptly to prevent moisture infiltration, which can lead to surface rust and corrosion underneath.

Can Different Liner Materials Be Combined for Optimal Rust Prevention?

Think of your liner setup like a fortress made of different stones. Combining materials like TPE with a sealed, custom-molded liner can create layers of defense. You’re reinforcing weak spots and ensuring water has no easy entry. By blending these options, you double your protection, making it tougher for rust to find a foothold. Just like a well-constructed fortress, your bed stays dry and rust-free longer.

What Are Signs of Improper Installation That May Lead to Rust?

You’ll notice signs of improper installation if gaps or uneven edges appear around the liner, allowing moisture to seep in. Cracks, tears, or shifting materials indicate poor fitment, creating spaces for water to collect. If you see water pooling or rust forming at edges or corners, it’s a sign the liner isn’t sealed properly. Regular inspections help catch these issues early, preventing rust and further damage.

How Often Should Drainage Systems Be Inspected and Cleared?

You should inspect and clear your drainage systems at least every three to six months, especially after heavy rains, snow melts, or seasonal changes. Regular checks help guarantee water flows freely, preventing pooling and moisture buildup beneath your bed mat or storage box. Keep an eye out for blockages, debris, or damage, and clear them promptly to maintain proper drainage. Consistent maintenance minimizes rust risk and extends the life of your truck bed.

Are There Specific Cleaning Agents Recommended for Maintaining Liners?

You should use mild, non-abrasive cleaners specifically designed for your liner material. Avoid harsh chemicals like bleach or solvents, as they can degrade the liner’s integrity. Instead, opt for gentle soaps or pH-neutral cleaners mixed with water. Regularly rinse and wipe down your liners to remove dirt, salt, and chemicals, helping prevent corrosion. Always follow the manufacturer’s recommendations to guarantee compatibility and maintain the liner’s protective qualities.

Conclusion

By blending proper planning, persistent inspections, and protective practices, you can prevent surface rust beneath your bed mat or storage box. Mastering moisture management, meticulous maintenance, and mindful materials make your metal surfaces more resilient. Stay vigilant, ventilate vigorously, and seal securely. With these simple, steadfast steps, you’ll safeguard your space, ensuring surfaces stay shiny, sound, and rust-free for years to come. Keep these tips in mind, and rust will remain a remote, rare rival.