The Toyota Tundra’s composite bed combines lightweight aluminum-reinforced materials with durable composites, offering great strength and resistance to rust and impact damage. You’ll benefit from its corrosion resistance, easy maintenance, and features like integrated lighting and power outlets. However, it can be slippery when wet, and repairs may be more specialized and costly. To understand how these strengths and weaknesses impact your hauling needs, keep exploring the details.

Key Takeaways

- The composite bed is lightweight, increasing towing capacity and fuel efficiency, but can be slippery when wet, affecting cargo stability.

- It offers superior corrosion resistance and durability compared to steel beds, reducing maintenance and repair costs over time.

- The impact-resistant composite surface withstands impacts better, but repairs may be more specialized and costly.

- Modern features like LED lighting and power outlets enhance safety and usability, though surface wear from abrasive cargo requires liners.

- Available in multiple sizes, the composite bed supports heavy payloads and load management, but may have size restrictions for oversized cargo.

Composition and Material Strength

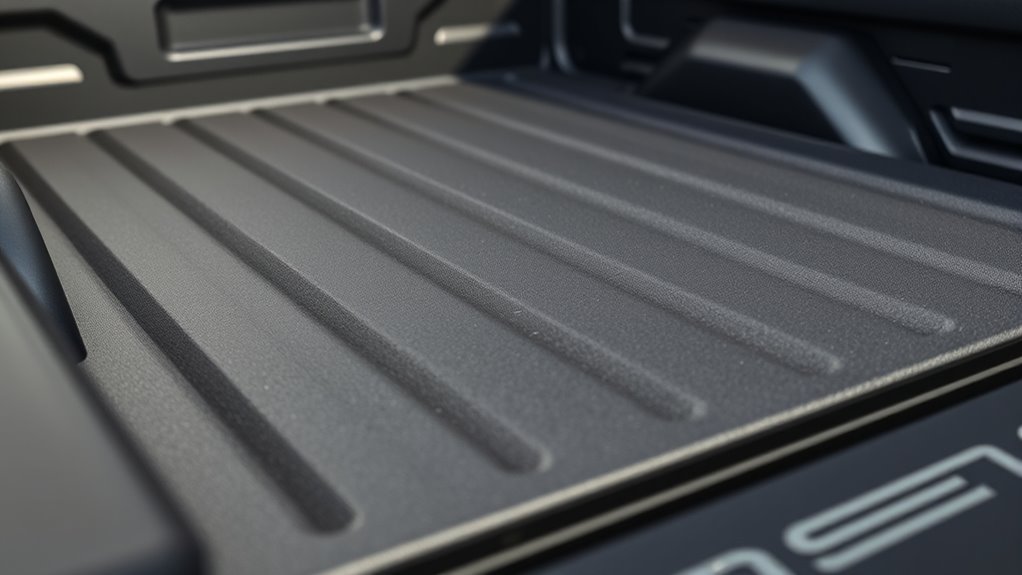

Have you ever wondered what makes the Toyota Tundra’s composite bed so strong and durable? It’s primarily built from Aluminum-Reinforced Sheet-Molded Composite (SMC), combining aluminum’s strength with a tough composite layer. This fusion offers greater impact resistance than pure aluminum, making it more resistant to dents, dings, and corrosion. The composite overlay acts as a protective barrier against environmental damage and rust, ensuring the bed stays intact over time. Despite being lightweight, the composite material supports hefty payloads—up to approximately 1,940 pounds in some configurations—without sacrificing strength. Additionally, material innovation in the composite bed contributes to improved longevity and performance. This construction not only enhances durability but also helps improve fuel efficiency and handling by reducing overall weight. Carefully engineered, the composite bed delivers a resilient foundation for your hauling needs.

Durability and Resistance to Damage

The Toyota Tundra’s composite bed is built to withstand tough hauling conditions, offering exceptional resistance to impact damage and environmental wear. Its impact-resistant composite overlay reduces the risk of dents and dings from heavy or irregular cargo, unlike traditional steel beds. The material’s rust-proof nature helps prevent corrosion, extending the bed’s lifespan even in wet or salty environments. Additionally, the composite surface absorbs shocks, protecting the bed from cracking or surface damage during heavy use. Its UV resistance prevents fading and deterioration over time. This durability lowers your maintenance needs and repair costs. Safe backup systems can ensure your vehicle remains operational during emergencies, complementing the durability of the composite bed.

The Toyota Tundra’s composite bed offers superior impact resistance, rust-proof durability, and UV protection for long-lasting tough hauling.

- Resists impact damage better than steel beds

- Rust-proof for extended longevity

- Absorbs shocks from cargo

- Fades and UV resistant

Practical Features and Functional Benefits

The Toyota Tundra’s composite bed includes practical features that make loading and working more convenient. With integrated LED lighting, you can see clearly even in low-light conditions, and the available power outlets let you run tools directly from the bed. Plus, the smooth-operating tailgate reduces wear and makes access effortless, saving you time and effort on every use. Deep-sky imaging techniques can even be employed to assess the durability of different bed materials under various conditions.

Integrated Bed Lighting

Integrated bed lighting enhances your visibility and safety during nighttime loading and unloading. It illuminates the entire bed area, helping you locate tools, cargo, or securing points without fumbling in the dark. This feature minimizes accidents and streamlines your workflow after sunset. The LED lighting is energy-efficient, ensuring long-lasting brightness without draining your battery. Additionally, it’s integrated seamlessly into the bed design, providing a clean and professional look. You’ll also benefit from:

- Automatic activation when the tailgate is open or via switches inside the cab

- Bright, white LED output for clear visibility

- Durable construction resistant to dust and moisture

- Easy operation with minimal controls for quick access

This feature boosts practicality, making night work safer and more efficient, whether you’re on-site or at a campsite. Innovative European Cloud Servers provide a reliable technology foundation that supports modern vehicle features like integrated lighting systems.

Bed Power Outlets

Ever find yourself needing power tools or charging devices on the go? The Tundra’s composite bed offers a convenient 120V power outlet, making it easy to run equipment directly from your truck. This practical feature enhances productivity during worksite tasks or outdoor adventures. The outlet is securely integrated into the bed, keeping cords organized and out of the way. To give you a clear view, here’s a quick overview:

| Feature | Benefit |

|---|---|

| 120V Power Outlet | On-site electrical access |

| Placement | Bed area for convenience |

| Power Capacity | Supports most portable tools |

| Weather Resistance | Designed for outdoor use |

| Ease of Use | Simple plug-in operation |

This feature boosts versatility, reducing the need for extra extension cords or power sources. Additionally, the outlet’s design considers electrical safety to ensure reliable operation in various conditions.

Smooth Tailgate Operation

A smooth-operating tailgate enhances your overall experience by making loading and unloading easier and safer. You’ll notice the controlled, damped movement that prevents abrupt drops or slams, reducing wear and tear. This feature minimizes noise and vibration, keeping operation quiet and comfortable. The tailgate’s design also promotes safety, preventing accidental injuries during use. Additionally, some models offer power-assisted tailgates, allowing you to open or close with the push of a button. This convenience is especially helpful when you’re carrying heavy or bulky loads. Features include:

- Dampers for controlled opening and closing

- Power tailgate option for effortless operation

- Reduced noise during use

- Enhanced safety with gradual movement

- Incorporating auditory feedback techniques can further improve the operation experience.

Limitations and Usage Considerations

Although the composite bed offers many advantages, there are some limitations you should consider before choosing it. The surface can become slippery when wet, making cargo stability more challenging unless you add accessories like mats or liners. Repairs to composite materials tend to be more specialized and costly compared to traditional steel beds, which might increase maintenance expenses. Heavy or abrasive cargo that is dragged across the surface can cause wear over time if protective liners aren’t used. Additionally, despite multiple length options, the bed dimensions may restrict oversized loads, requiring careful planning. Since composite beds are less common than steel, you’ll need to adjust your maintenance and cargo handling routines accordingly. Understanding these factors helps you make an informed decision about whether a composite bed suits your hauling needs.

Configurability and Size Options

The Toyota Tundra’s composite bed offers a range of size options designed to meet diverse hauling needs. You can choose from three bed lengths: 5.5 feet on CrewMax models, 6.5 feet on Double Cab and CrewMax, and 8.1 feet on Double Cab configurations. This variety allows you to select the best fit for your cargo and parking space constraints. The bed width between wheel wells remains consistent at approximately 48.5 inches, ideal for carrying standard sheets of plywood or drywall flat. Payload capacities vary based on bed size and cab type, reaching up to around 1,940 pounds. Some trims include features like adjustable deck rails and fixed tie-down points, enhancing load management and security. These options enable customization tailored to your specific hauling and storage needs, and understanding composite bed materials can help you better care for and maintain this innovative truck feature.

Impact on Performance and Maintenance

Weight savings from the composite bed directly improve your vehicle’s towing capacity and handling, making every drive more efficient. Since the bed is lighter, your Tundra can tow heavier loads without sacrificing stability or fuel economy. The composite material also reduces the need for frequent rust inspections and treatments, as it resists corrosion better than steel. Maintenance becomes easier because the surface is simple to clean and less prone to chipping or rust buildup. Free Floating Bed lighting enhances nighttime visibility, speeding up loading and unloading while improving safety. Overall, this durable construction minimizes repair costs and extends the bed’s lifespan. As a result, your vehicle maintains its value longer, with less time and money spent on upkeep over its lifetime.

Frequently Asked Questions

How Does the Composite Bed Compare to Traditional Steel Beds in Cost?

You’ll find that composite beds are generally more expensive upfront than traditional steel beds. While they cost more initially, they offer benefits like lower maintenance costs, corrosion resistance, and durability, which can save you money over time. The higher price reflects the advanced materials and manufacturing process. So, although you pay more at first, you might save on repairs, repainting, and replacements later.

Can the Composite Bed Be Recycled or Repurposed After Vehicle End-Of-Life?

Did you know composite materials can be recycled? Yes, the Toyota Tundra’s composite bed can be recycled or repurposed after the vehicle’s end-of-life. You’ll find that the aluminum-reinforced SMC can be processed to recover metals, while the composite layer may be repurposed into other products or ground down for use in new materials. Recycling helps reduce waste, making the composite bed an environmentally friendly choice even after your truck’s retired.

What Maintenance Practices Are Recommended for Optimal Composite Bed Longevity?

To keep your composite bed in top shape, regularly clean it with mild soap and water, avoiding harsh chemicals. Inspect for scratches, cracks, or signs of wear, and use protective mats or liners for abrasive loads. Keep the bed dry to prevent moisture buildup, and avoid dragging heavy or sharp objects directly across the surface. Proper maintenance helps preserve impact resistance, appearance, and overall durability, extending your bed’s lifespan.

Are There Aftermarket Accessories Specifically Designed for the Composite Bed Surface?

Yes, there are aftermarket accessories designed for your composite bed surface. You can add bed mats, protective liners, and tie-down systems tailored for composite materials. These accessories help prevent slipping, protect against scratches, and secure cargo effectively. Make sure to choose products compatible with composite surfaces to avoid damage. Installing these accessories enhances your bed’s durability, safety, and usability, ensuring you get the most out of your truck’s features.

How Does the Composite Bed Affect Overall Vehicle Resale Value?

Think of your vehicle like a trusty steed; a durable composite bed adds value that echoes tales of resilience. It resists rust and damage, making your Tundra more appealing to buyers. This longevity and low-maintenance feature enhance resale value, showing you’ve taken good care of it. Plus, modern buyers appreciate innovative materials, so your composite bed can be a selling point that keeps your truck ahead of the pack.

Conclusion

The Toyota Tundra’s composite bed offers impressive strength and resistance, reducing dents and rust. Its durability means fewer repairs, saving you time and money. With multiple size options, you can customize your truck for any job. However, keep in mind that heavier loads may impact fuel efficiency. Did you know that the composite bed reduces weight by up to 60 pounds compared to steel? This small difference can improve your truck’s performance and longevity.