To secure your truck bed load at high speeds or in strong winds, choose heavy-duty, waterproof tarps with reinforced eyelets and guarantee they’re tightly stretched evenly over the load, extending beyond edges for protection. Use multiple ratchet straps arranged diagonally and across the load’s center, tightening them securely. Regularly check tension and adjust as needed during transit. Proper load placement and aerodynamic considerations will help reduce wind impact—continue on to learn more about ideal securement strategies.

Key Takeaways

- Use heavy-duty, waterproof tarps with reinforced eyelets, ensuring proper placement and tightness to prevent flapping and exposure.

- Apply multiple high-rated ratchet straps across the load’s center and perimeter, checking tension regularly during transit.

- Position taller cargo near the cab and use wind deflectors to reduce wind resistance and turbulence.

- Ensure overhang complies with legal limits, and mark with warning flags or lights for visibility in high winds.

- Conduct thorough inspections of tie-downs and securement methods before and during travel to maintain load stability.

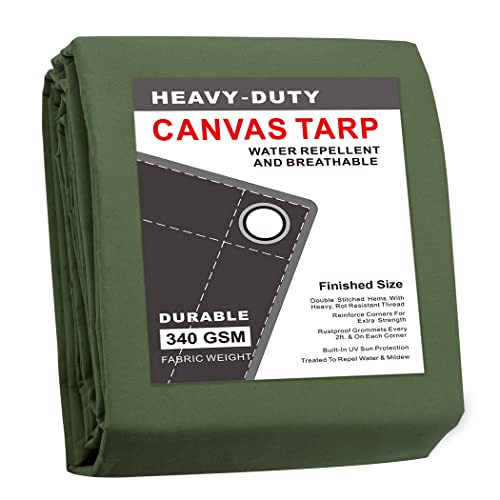

CARTMAN Finished Size 6×8 Feet Canvas Tarp with Rustproof Grommets, Heavy Duty Multipurpose Tarpaulin Cover for Canopy Tent, Roof, Camping, Woodpile

HEAVY DUTY – Our canvas fabric boasts a basic weight of 10oz and a finished weight of 12oz….

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Selecting the Right Tarp and Materials for High-Speed Transport

Choosing the right tarp for high-speed transport is essential to guarantee your load stays secure and protected. You need a heavy-duty, waterproof tarp with reinforced eyelets for durability and longevity. Before each use, inspect it carefully for tears or wear — any damage can lead to failure during transit. Highway-rated tarps, designed to withstand speeds over 65 mph, provide ideal wind resistance. Ensure the tarp covers your load squarely, with enough extension beyond the edges to prevent exposure. The material’s thickness and quality directly impact its ability to resist gusts and weather exposure. Using the right tarp isn’t just about coverage; it’s about selecting a durable, reliable material that can handle the demands of high-speed travel and rough conditions. Proper tarp securing techniques are also vital to prevent shifting or loosening during transit.

Ratchet Straps Heavy Duty, Tie Down Straps Ratchet Set, 2200 LB Break Strength, Safety Lock S Hooks, Best for Moving, Securing Cargo, Kayaks, Mountain (4 Pack)

SAFETY LOCK HOOK DESIGN – No need to worry about damaging your tools or vehicle surfaces while securing…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Proper Tarp Placement and Securing Techniques for Wind Resistance

Proper tarp placement is essential for wind resistance, so you must guarantee the tarp is centered and extends sufficiently beyond the load edges to prevent exposure. Ensure the tarp covers the entire load with at least a 6-12 inch overhang on all sides. Tighten the tarp before securing the edges, minimizing slack that could catch wind. Use a combination of bungee cords and ratchet straps at key points to maintain tension. Proper edge protection, like edge guards, helps prevent fraying and distributes pressure evenly. Consider the following placement tips:

| Tarp Area | Securing Method | Additional Tips |

|---|---|---|

| Center | Ratchet straps | Keep taut for flat surface |

| Edges | Bungee cords | Extend beyond load for coverage |

| Corners | Reinforced eyelets | Avoid slack and billowing |

Deejecsun in-Channel Window Rain Guards Fit for Chevy Silverado 1500/GMC Sierra 1500 2019-2026 Crew Cab Extra Durable Window Deflectors Window Visors Vent Visors Vent Shades Truck Accessories

【Compatibility】The Deejecsun Window Rain Guards fit for Truck Chevy Chevrolet Silverado Crew Cab 2019-2026 ; GMC Sierra Crew…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Utilizing Multi-Layer Strap Configurations for Load Stability

Implementing multi-layer strap configurations considerably enhances load stability by creating a tension network that evenly distributes forces across the entire cargo. You should use multiple cross-straps to connect different points of the load, preventing twisting and shifting during transit. Select ratchet straps rated for the cargo’s weight and type, ensuring they’re tight enough to hold the load firmly without damaging it. Place the straps strategically—across the middle and perimeter—to maintain flatness and prevent lift from strong winds. Wrapping bungee ropes around the edges adds extra security, especially at corners. Always double-check tension after tightening and during travel. This layered approach minimizes load movement, reduces strain on individual straps, and markedly improves stability at highway speeds or in high winds. Proper load securing techniques are essential for ensuring safety and compliance during transport.

30 Pack Plastic Corner Protectors and Edge Protectors for Flatbed Trucks, Compatible with 4 Inch Ratchet Straps, Cargo Load Guard

【Premium Material】These plastic corner protectors are made of high-density polyethylene (HDPE) featuring waterproof, UV-resistant, and freeze-resistant properties. All…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Managing Aerodynamics and Wind Flow to Minimize Lift and Flutter

You can reduce lift and flutter by carefully positioning your load, keeping taller items near the cab to lessen wind resistance. Using wind deflectors or front fairings helps redirect airflow, preventing turbulence around the cargo. Proper load placement combined with strategic wind deflection techniques keeps your load stable at highway speeds. Additionally, securing your load with appropriate tie-downs and restraints ensures even distribution of force and minimizes movement caused by aerodynamic forces.

Load Positioning Strategies

Managing aerodynamics and wind flow is essential for securing a truck bed load, especially at highway speeds where wind resistance can cause lift and flutter. To minimize these effects, position your load low and close to the truck bed floor to reduce wind catch. Keep taller items near the cab to streamline airflow and prevent turbulence. Distribute weight evenly across the bed to improve stability and prevent shifting. Avoid overhanging cargo that can catch wind or create imbalance. Use proper tie-downs to maintain load integrity and prevent movement during gusts. Align items to match the truck’s natural airflow lines, reducing drag and lift. Additionally, understanding aerodynamic principles can help you optimize load placement for better stability. By optimizing load placement, you improve aerodynamic efficiency and decrease the risk of load displacement caused by high winds.

Wind Deflection Techniques

Effective wind deflection techniques are essential for reducing lift and flutter during highway transport. Proper aerodynamic management minimizes wind resistance and keeps your load stable at high speeds. To optimize airflow:

- Position tall or high-profile loads near the cab to reduce drag and prevent flutter.

- Add diagonal straps to stabilize the load and prevent wind lift.

- Install wind deflectors or front fairings to redirect airflow around the load, decreasing turbulence.

- Use aerodynamic accessories designed specifically for truck loads to improve airflow efficiency and stability.

These strategies help maintain load stability and prevent dangerous flutter or lift caused by gusts. Ensuring smooth airflow over your cargo reduces stress on securing straps and enhances overall safety. Regularly check the positioning and condition of deflectors and straps, especially during long trips or when wind conditions worsen. Proper aerodynamic techniques keep your load secure and your journey safer.

Monitoring Tension and Conducting Regular Checks During Transit

To guarantee your load remains secure throughout transit, it’s essential to monitor strap tension continuously and conduct regular checks. As you drive, keep an eye on your tension gauges or feel for slack or tightness in the straps. Temperature changes and wind can affect tension, so recheck after long stretches or gusty conditions. Verify anchor points and strap connections frequently to ensure nothing has shifted or loosened. When conditions are wet or humid, increase tension slightly—about 10%—to compensate for reduced grip. Use friction pads or slip-resistant mats to prevent lateral shifting. Regularly inspect straps, buckles, and tarp integrity, especially after hitting bumps or rough patches. Proactive monitoring keeps your load stable and prevents accidents or damage during high-speed or windy conditions. Incorporating connected monitoring devices can provide real-time updates on tension and safety status, enhancing overall security during transit.

Ensuring Regulatory Compliance and Proper Documentation

You need to check local overhang rules and secure the necessary permits before hitting the road to avoid fines or delays. Make sure your tie-downs meet regulations, especially for heavy loads, with proper placement and quantity. Staying compliant guarantees a smooth trip and helps you avoid costly penalties or safety violations. Additionally, understanding total‑cost clarity can help you plan for reliable and cost-effective load securing equipment.

Overhang and Permits

Overhanging loads must comply with local regulations to guarantee safe transport and avoid legal penalties. You need to verify rules for maximum overhang length, required signage, and lighting. Failure to follow these can result in fines or load rejection. To stay compliant, consider these steps:

- Check with your state’s Department of Transportation for specific overhang limits and signage requirements.

- Obtain any necessary permits if your load exceeds legal overhang thresholds.

- Use appropriate warning flags, lights, or signs to alert other drivers of the overhang, especially at night or in poor visibility.

- Ensuring proper color accuracy and clear documentation of permits can further improve safety and compliance.

Always document permits and compliance measures. Proper documentation proves you’ve followed regulations, reducing liability and ensuring smooth transit. Stay informed, stay compliant.

Tie-Down Regulations

Ensuring compliance with tie-down regulations is essential for safe and legal transportation of cargo. You must check local Department of Transportation rules for specific requirements, especially for overhang or oversized loads. Typically, at least four tie-downs are needed for equipment over 10,000 pounds, with proper placement near the front and rear or on designated mounting points. Some states require permits or signage for extended loads. When restraining articulated vehicles, ensure equipment stays in position throughout transit. Proper documentation, such as permits or inspection records, helps verify compliance if questioned. Familiarity with cargo securement standards is crucial to meet safety guidelines and prevent violations. Failing to meet these regulations can lead to fines, load shifts, or accidents. Always double-check tie-down counts, placement, and documentation before hitting the road to make certain safety and avoid legal issues.

Frequently Asked Questions

How Do I Choose the Best Tarp for Extreme Highway Speeds?

You should choose a heavy-duty, waterproof tarp made from durable material with reinforced eyelets for strength. Opt for highway-rated tarps designed to withstand speeds exceeding 65 mph, ensuring they resist wind and weather. Make sure the tarp covers the load completely with extra coverage beyond the edges. Properly securing it using a front-to-back sequence with tensioned straps helps prevent billowing and improves stability during high-speed travel.

What Are the Signs of Load Shifting During Transit?

You’ll notice load shifting when the tarp appears loose or billows excessively, indicating movement. If you see straps slackening or hear unusual noises like rattling, your load isn’t secure. You might also feel uneven handling or notice the load shifting during stops or turns. Regularly check the tension of your straps and the position of your load to catch shifting early, ensuring safe transport and preventing accidents.

How Can I Prevent Tarp Tearing From Sharp Cargo Edges?

You can prevent tarp tearing from sharp cargo edges by wrapping the edges with edge protectors or padding, acting as a shield to keep the material safe. Make sure to secure the tarp tightly over the load, with enough coverage beyond the edges. Regularly inspect for tears and replace damaged sections promptly. Remember, a stitch in time saves nine, so proactive protection keeps your load secure and your trip smooth.

What Safety Precautions Should I Take Before Starting a Long Haul?

Before starting your long haul, you should thoroughly inspect all securing equipment and the load. Make sure tarps are intact, properly tensioned, and securely fastened to prevent shifting. Verify all straps, bungee cords, and tie-downs are rated for the load’s weight and in good condition. Check for proper edge protection and wind resistance measures. Additionally, plan your route to avoid extreme weather and overhang violations, ensuring a safe, compliant journey.

How Do Weather Conditions Affect Strap Tension Over Time?

Weather conditions directly impact your strap tension during transit. When it rains or gets wet, increase your strap tension by about 10% because moisture reduces grip and holding capacity. Temperature fluctuations from heat to cold can cause straps to stretch or contract, so regularly check and adjust tension accordingly. Cold weather may tighten straps, while heat may loosen them, so ongoing inspection guarantees your load stays secure throughout your journey.

Conclusion

By following these tips, you can keep your load secure even in high winds or at highway speeds. For example, imagine you’re hauling lightweight equipment and neglect to tighten your straps—suddenly, gusts lift your tarp and shift your cargo. Regular checks and proper securing techniques prevent this. Stay proactive, monitor your load, and make certain of compliance, so your journey remains safe and your cargo arrives intact, no matter what the weather throws at you.