If you want to protect your truck from rust, undercoating can create a barrier against moisture, salt, and debris that cause corrosion. It’s best to apply it on a clean, dry surface, especially if your vehicle is new or rust-free. However, undercoating doesn’t fix existing rust, so consider rust-proofing if you already have rust issues. To learn more about choosing the right approach for your truck, keep exploring the details below.

Key Takeaways

- Undercoating provides a protective barrier against moisture, salt, and debris, preventing rust on your truck’s undercarriage.

- It is most effective as a preventative measure on new or rust-free trucks, not for treating existing rust.

- Combining undercoating with rust-proofing offers enhanced protection, especially in harsh, salty environments.

- Proper surface preparation—clean, dry, and rust-free—is essential for maximum undercoating effectiveness.

- Regular undercoating can extend your truck’s lifespan, reduce noise, and maintain resale value in rust-prone areas.

Rust-Oleum 248657-6PK Stops Rust Undercoating Spray, 15 oz, Rubberized Black, 6 Pack

Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Understanding the Purpose of Undercoating for Trucks

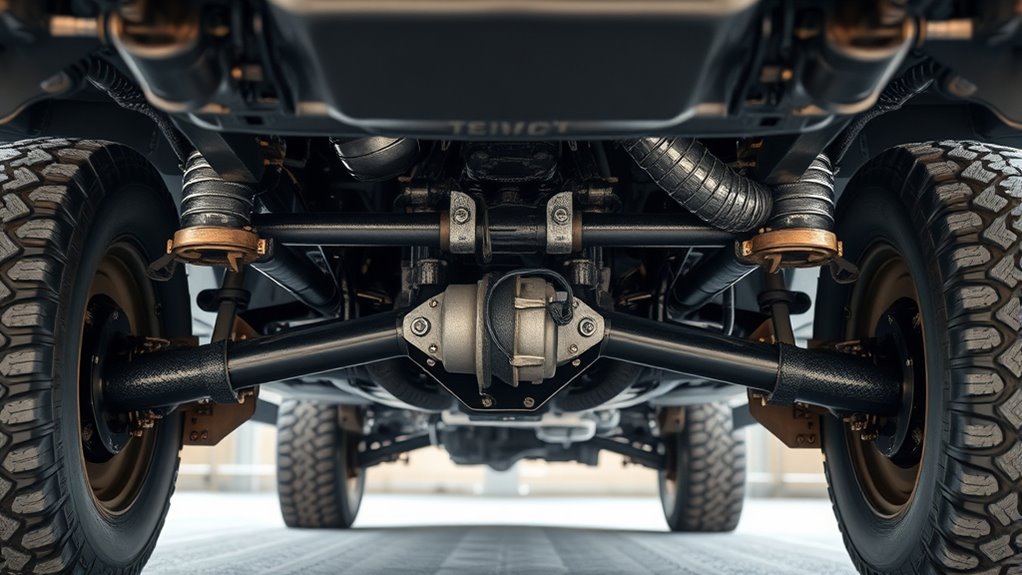

Undercoating serves a crucial role in protecting your truck from the harsh elements it faces on the road. It creates a protective barrier on your vehicle’s undercarriage, shielding it from moisture, road salt, and debris that can cause rust and corrosion over time. By applying undercoating, you prevent harmful substances from reaching the metal surfaces, which helps extend your truck’s lifespan. Most products are rubberized, oil-based, or lanolin-based, designed to stick well and withstand harsh conditions. Proper application to a clean, dry underbody is essential for maximum effectiveness. Keep in mind, undercoating is mainly preventive; it’s most beneficial if done before rust or damage appears, especially if you frequently drive in winter or in areas with salty roads. Additionally, choosing proper application techniques can significantly improve the protective qualities of the undercoating.

Krown, Rust Inhibitor, Rust Proofing, Anti-Rust Coating, Corrosion Protection, Automotive Undercoating, Truck & Car Rust Prevention, Self-Healing, No Solvents, Underbody Protection (1 Gallon)

Long-Lasting Rust Protection: Krown Rust Protection & Lubricant creates a durable protective barrier that resists breaking, chipping, and…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Comparing Undercoating and Rust-Proofing: Which Is Right for You?

While undercoating and rust-proofing both protect your truck from rust and corrosion, they serve different purposes and are suited for different situations. Undercoating acts as a barrier, preventing moisture, salt, and debris from reaching the metal, making it ideal for new vehicles or preventative maintenance. Rust-proofing, on the other hand, targets existing rust with chemical treatments that neutralize or stop its spread, which is better if rust has already formed. If you live in harsh climates with lots of snow, salt, or moisture, combining both methods offers the best protection. Choose undercoating when your vehicle is clean and rust-free, and rust-proofing if you notice rust starting to appear. Understanding your needs helps you decide which approach will keep your truck in top shape longer.

Barrier Bond – Rubberized Undercoating Sound Deadener Kit, 28oz 4-Pack, Black Spray, Vehicle Undercoating, with Spray Gun

Paintable & Top Coat Compatible: Easily paintable, compatible with most top coats for a seamless, customized finish.

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Evaluating the Effectiveness and Types of Undercoating Products

Understanding the different types of undercoating products helps you choose the right solution for your vehicle’s needs. Each type offers unique benefits and durability. Rubberized coatings create a thick, tough barrier but may crack over time. Oil-based products, like NH Oil Undercoating, penetrate crevices and remain flexible, providing long-lasting protection. Lanolin-based options, such as Fluid Film, are waterproof, environmentally friendly, and can stop existing rust from spreading. Here’s a quick comparison: European cloud innovation emphasizes the importance of using reliable and sustainable methods to protect assets like your vehicle.

| Type | Pros | Cons |

|---|---|---|

| Rubberized | Thick, durable, good impact resistance | Can crack, less flexible |

| Oil-based | Penetrates, remains flexible, long-lasting | May require reapplication |

| Lanolin-based | Waterproof, eco-friendly, stops rust | Less impact resistance |

| All Types | Protects against moisture and salt | Proper application needed |

Fluid Film 1 Gallon Can Rust Inhibitor Rust Prevention Anti Corrosion Anti Rust Coating Undercoating Underbody Rust Proofing Corrosion Protection for Truck Snow Blower Mower Car Semi Tractor Bus

Rust Preventive Lubricant

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

When and How to Apply Undercoating to Your Truck

Applying undercoating at the right time guarantees maximum protection for your truck. The best moment is when your undercarriage is clean, dry, and free of rust. Before applying, thoroughly wash your truck to remove dirt, salt, and debris, then let it dry completely. Ideally, do this in mild weather—avoid freezing or extreme heat—so the coating adheres properly. If you notice existing rust, address it with rust converter or rustproofing first. For new trucks, undercoating can be done right after purchase or before winter hits. For older vehicles, ensure the surface is clean and rust-free. Proper preparation ensures the undercoating bonds well and provides lasting protection. Additionally, understanding the role of contrast ratio can help you evaluate how well your protective coatings will perform in different lighting conditions. Professional application is recommended if you’re unsure or dealing with extensive rust.

Weighing the Benefits and Limitations of Undercoating

Considering the benefits and limitations of undercoating helps you decide if it’s the right choice for your truck’s protection. Undercoating can effectively prevent rust, extend your vehicle’s lifespan, and reduce road noise. However, it’s not a cure-all; it doesn’t remove existing rust and requires proper application to be effective. Be aware that some products may crack or wear over time, especially if applied improperly. Additionally, in areas with minimal exposure to moisture or salt, the cost may outweigh the benefit. Proper surface preparation and choosing high-quality products can significantly influence the effectiveness and durability of the undercoating application process.

Frequently Asked Questions

Can Undercoating Be Applied to an Already Rusted Truck?

Yes, you can apply undercoating to an already rusted truck, but it’s not a cure for rust. First, you need to remove loose rust and debris, then treat the affected areas with a rust converter or rust-proofing chemical. Once the rust is neutralized and the surface is clean and dry, applying undercoating can help prevent further rusting and provide added protection. However, addressing existing rust is essential for long-term durability.

How Long Does Undercoating Typically Last Before Needing Reapplication?

Undercoating typically lasts about 2 to 5 years before you should consider reapplying, depending on the product used and your driving conditions. If you drive in harsh environments like snow, salt, or rough terrains, you’ll need to recoat more frequently. Regular inspections help you spot any damage or wear, ensuring your undercarriage stays protected. Keep an eye on the condition, and reapply as needed to maintain peak rust prevention.

Is Professional Undercoating More Effective Than DIY Methods?

Ever wondered if a professional touch can make a difference? Yes, professional undercoating is more effective than DIY methods. Experts ensure thorough, even application, reaching hard-to-access areas and using high-quality products. They also inspect your vehicle for existing issues, providing tailored solutions. While DIY is cheaper, it often lacks the precision and durability of professional work, ultimately offering better long-term protection for your truck’s undercarriage.

Does Undercoating Affect Vehicle Warranty or Insurance Coverage?

Undercoating generally doesn’t affect your vehicle warranty or insurance coverage if it’s done correctly and with approved products. However, if improper application causes damage or if rust appears due to poor work, it might void parts of your warranty. Always check your warranty and insurance policies beforehand. You should also use professional services or follow manufacturer guidelines to guarantee your undercoating doesn’t interfere with coverage.

Are There Environmentally Friendly Undercoating Options Available?

Yes, there are environmentally friendly undercoating options available. You can choose products like lanolin-based or water-based coatings, which are non-toxic, biodegradable, and environmentally safe. These options provide effective rust protection while minimizing environmental impact. When selecting an undercoating, look for labels indicating eco-friendliness or non-toxicity. Using these environmentally friendly products helps protect your vehicle and the environment without compromising on durability or performance.

Conclusion

Deciding whether to undercoat your truck comes down to understanding the benefits, recognizing the limitations, and weighing the costs. If you want to protect your vehicle from rust, extend its lifespan, and maintain its value, then undercoating can be a smart choice. If you’re looking for a simple, cost-effective solution or live in a dry climate, it might not be necessary. Ultimately, it’s about making an informed decision that fits your needs, your budget, and your driving environment.