To make your truck engine last 300,000 miles, stick to the manufacturer’s maintenance schedule, use high-quality oils, and replace worn parts early. Practice smooth driving habits, avoid aggressive acceleration, and manage loads carefully. Keep your engine clean and monitor crucial components regularly. Proper cooling, timely fluid changes, and choosing durable, reputable parts also matter. If you stay consistent with these tips, you’ll discover how to maximize your engine’s longevity over the miles ahead.

Key Takeaways

- Follow the manufacturer’s recommended maintenance schedule diligently, including regular oil changes and inspections.

- Practice smooth driving habits, avoiding rapid acceleration, high RPMs, and abrupt stops.

- Keep the engine clean and monitor critical components like belts, hoses, and cooling systems regularly.

- Use high-quality, durable parts and fluids suited for your driving conditions.

- Protect the engine from harsh environments and perform timely repairs to prevent small issues from escalating.

Valvoline MaxLife High Mileage 5W-30 Synthetic Blend Motor Oil 5 Quart

Formulated for engines with 75,000 miles or more, Valvoline MaxLife High Mileage synthetic blend is formulated with seal…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Stick to the Manufacturer’s Maintenance Schedule

Sticking to the manufacturer’s recommended maintenance schedule is vital for maximizing your truck engine’s lifespan. Regular oil changes, filter replacements, and inspections prevent dirt, debris, and harmful deposits from building up inside the engine. By following these guidelines, you can catch potential issues early before they turn into costly repairs. Keep in mind that major problems often surface after around 200,000 miles or 12 years, so preventive maintenance is key to avoiding these costly failures. Regularly check and service components like belts, hoses, and cooling systems as advised. Understanding maintenance schedules is essential for effective vehicle care. Consistency is essential—skipping scheduled maintenance can accelerate wear, reduce efficiency, and shorten your engine’s life. Following the schedule ensures your engine runs smoothly and reliably for hundreds of thousands of miles. Additionally, adhering to recommended service intervals helps maintain engine performance and fuel efficiency over the long term. Staying proactive with your vehicle’s maintenance can also help identify early signs of trouble, potentially saving you from expensive repairs down the road. Incorporating smart maintenance technology can further optimize your upkeep and alert you to issues before they become serious.

Dorman 54002 Engine Coolant Recovery Kit Universal Fit

Great for modification or replacement – this engine coolant recovery tank kit catches and returns coolant on cars,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Choose High-Quality Oils and Fluids

Choosing high-quality oils and fluids plays a significant role in extending your truck engine’s lifespan. Premium synthetic oils, like Pennzoil Ultra Platinum or Amsoil Signature, contain anti-wear additives that reduce friction and engine wear over thousands of miles. Regularly changing these fluids prevents buildup of soot, acids, and contaminants that can accelerate engine deterioration. It’s essential to use oils and fluids specified by your manufacturer, considering heavier-duty options for high-mileage engines. Don’t neglect other crucial fluids, such as transmission, transfer case, and differential oils, which also impact overall engine health. Proper fluid maintenance is vital for preventing corrosion and ensuring efficient operation. Adequate lubrication reduces internal wear and helps maintain engine integrity over time. Routine inspections of body jewelry measurements and materials ensure that components fit correctly and do not cause additional strain or damage. Color accuracy impacts the overall image quality of projectors and is crucial for maintaining clear, vibrant visuals. Additionally, using vetted wave and wind data can help monitor environmental conditions that may affect fluid performance and engine longevity. By investing in top-tier oils and sticking to recommended intervals, you help maintain ideal lubrication, prevent corrosion, and support the engine’s internal components, setting the stage for a long, reliable service life.

Heavy-Duty Storage Straps – 9 Pack Hook and Loop Hanging Extension Tool Cord Straps Organizer for Cable Management, Rope, Hoses, RV and Garage Organization – includ 10-inch/13-inch /17-inch

ORGANIZING: This heavy-duty storage belt is perfect for use in garages, yards, shops, sheds, boats, RVs, and trucks,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

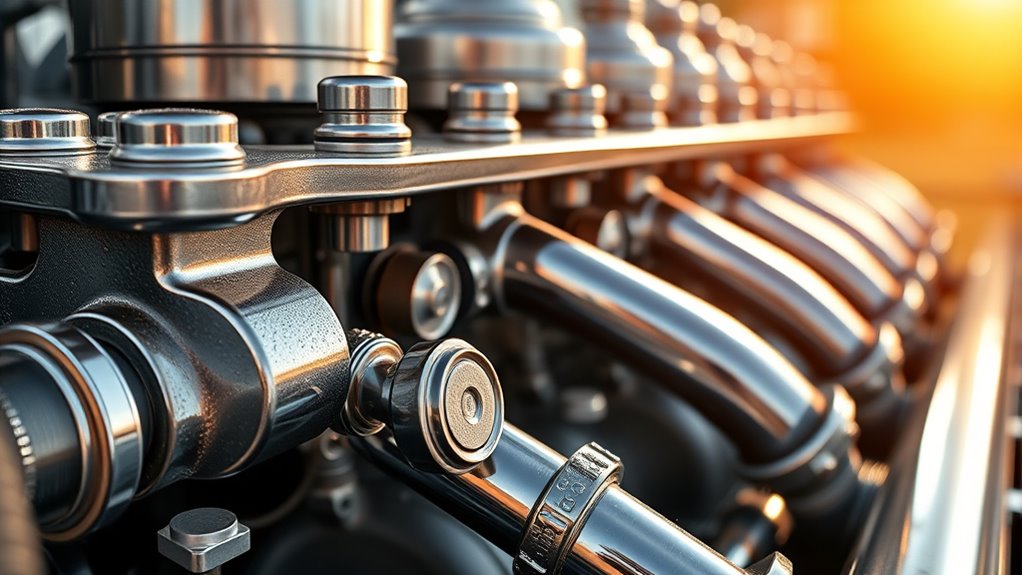

Monitor and Replace Worn Components Early

You should regularly inspect your engine for signs of wear and address issues before they worsen. Replacing worn components like belts, seals, and bearings early can prevent costly failures and keep your engine running smoothly. Staying proactive with parts replacement is key to reaching that 300,000-mile milestone. Incorporating routine engine maintenance checks ensures that minor problems are caught early, maintaining optimal performance over the long haul. Additionally, using high-quality spare parts designed for durability can significantly extend your engine’s lifespan. Implementing proper preventive measures based on manufacturer guidelines further enhances engine longevity and reliability. Regularly monitoring component wear allows for timely interventions and avoids unexpected breakdowns, ensuring your engine remains in top condition for the long run. Engaging with industry trends can also help you stay informed about the latest advancements in engine technology and maintenance techniques.

Regular Wear Inspections

Regular wear inspections are essential for maintaining your truck’s engine health over the long haul. By routinely checking critical components like belts, hoses, and seals, you can catch early signs of deterioration before they cause major issues. Pay close attention to your alternator, water pump, and timing chain for any unusual noises, leaks, or looseness. Monitoring these parts allows you to replace worn items proactively, preventing sudden failures that could leave you stranded or damage the engine. Regular inspections also include checking fluid levels and condition, which helps identify early wear. Staying vigilant about component wear ensures your engine stays in top shape, reducing the risk of costly repairs and extending its lifespan beyond 300,000 miles. Consistent early intervention keeps your engine running smoothly for the long haul. Additionally, practicing methodical testing helps identify potential issues before they escalate, further safeguarding your engine’s longevity.

Timely Parts Replacement

Monitoring and replacing worn components early can considerably extend your truck’s engine lifespan. Regularly inspect parts like water pumps, alternators, belts, seals, and bearings. When you notice signs of wear—such as squealing, leaks, or abnormal vibrations—don’t delay repairs. Replacing these parts promptly prevents minor issues from escalating into major failures that could damage your engine or leave you stranded. Paying close attention to tensioners, idler bearings, and cooling system components, as their failure can cause overheating or breakdowns, is essential. Keeping up with timely replacements also helps maintain ideal engine performance and fuel efficiency. By proactively addressing wear items, you reduce the risk of costly repairs and keep your engine running smoothly well beyond 200,000 miles. Additionally, understanding engine components’ importance can aid in prioritizing maintenance tasks effectively, especially when considering preventive maintenance strategies and their role in vehicle longevity. Staying informed about nanotechnology advancements can also lead to innovative solutions for extending engine life through improved materials and coatings. Regularly consulting maintenance schedules tailored to your specific vehicle model can further optimize your proactive approach.

Valvoline MaxLife Multi-Vehicle ATF Full Synthetic Automatic Transmission Fluid 1 Gallon

For use in 95% of vehicles including most CVTs in operation with US registered light duty applications

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Practice Smooth Driving Habits and Load Management

To extend your engine’s life, you need to practice smooth driving habits and load management. Maintaining steady speeds, avoiding sudden accelerations, and not overloading your truck reduce stress on engine components. These practices help prevent unnecessary wear and keep your engine running reliably for hundreds of thousands of miles. Additionally, paying attention to engine water chemistry and ensuring proper cooling system maintenance can further enhance engine longevity. Incorporating Free Floating principles in your maintenance approach can also help optimize engine performance over time. Regularly monitoring coolant quality and maintaining proper mixing ratios can prevent corrosion and overheating, further supporting your engine’s durability. Being aware of fluid analysis can provide early warnings of potential issues, allowing for timely interventions.

Maintain Steady Speeds

Maintaining a steady speed and practicing smooth driving habits can considerably extend your truck engine’s lifespan. When you avoid rapid acceleration and sudden braking, you reduce stress on engine components and minimize heat buildup. Consistent speeds also help maintain ideal fuel and oil flow, preventing unnecessary wear. Managing your load properly and staying within recommended RPMs further protects your engine from strain. Here’s a quick look at how steady driving benefits your truck:

| Benefit | Why It Matters |

|---|---|

| Reduced Engine Strain | Less wear on pistons, bearings, and valves |

| Lower Fuel Consumption | Fewer fluctuations in engine workload |

| Minimized Thermal Shock | Consistent speeds prevent overheating and cooling cycles |

Avoid Sudden Acceleration

Sudden acceleration puts unnecessary stress on your truck’s engine and drivetrain, accelerating wear on pistons, valves, and bearings. When you press the gas pedal abruptly, you force the engine to work harder than necessary, increasing heat and mechanical strain. Over time, this can lead to faster component degradation and higher repair costs. To extend your engine’s lifespan, practice smooth, gradual acceleration, especially from a stop or when merging. Keep your driving consistent and avoid aggressive throttle inputs. Also, managing your load appropriately helps prevent sudden surges of power that can stress the engine. By maintaining steady acceleration and load control, you reduce internal wear, improve fuel efficiency, and help your engine reach and surpass the 300,000-mile mark.

Manage Heavy Loads

Managing heavy loads effectively is essential for prolonging your truck’s engine life. Overloading or abrupt load changes put extra stress on engine components, increasing wear and risking failure. To keep your engine running smoothly over thousands of miles, focus on load management and driving habits.

- Distribute weight evenly to reduce strain on axles and engine.

- Avoid sudden acceleration or deceleration when hauling heavy loads.

- Use proper gear shifting to minimize engine RPM spikes.

- Limit abrupt stops and starts, especially on steep grades.

- Ensure loads don’t exceed your truck’s maximum capacity.

Focus on Engine Design and Manufacturing Durability

Engine design and manufacturing quality play a crucial role in how long your truck engine can last. A well-designed engine uses durable components, balanced tolerances, and proven engineering principles to reduce wear and prevent failures over time. Manufacturers like Toyota and Chrysler have built engines known for longevity, often surpassing 300,000 miles with proper care. Simpler, robust designs tend to outperform complex, high-tech engines in durability. High-quality materials and precise manufacturing processes ensure components resist heat, friction, and stress. Choosing an engine with a reputation for durability gives you a solid foundation for reaching high mileage. When the build quality is high, your engine can better withstand daily driving challenges, making maintenance easier and extending its lifespan considerably.

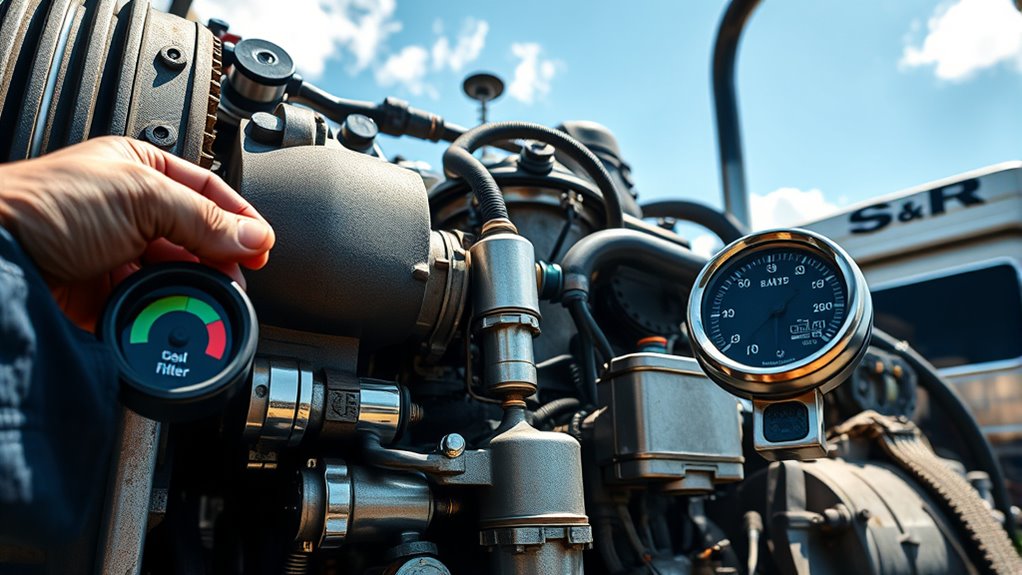

Regularly Inspect and Maintain Cooling Systems

A well-designed engine can last over 300,000 miles, but neglecting the cooling system can quickly undermine that durability. Regularly inspecting and maintaining your cooling system ensures it functions properly, preventing overheating and internal damage. Check coolant levels monthly, looking for leaks or contamination. Flush and replace coolant as recommended, typically every 2-3 years, to prevent corrosion. Inspect hoses and clamps for cracks or wear, replacing any that show signs of deterioration. Keep the radiator clean to maximize airflow, and ensure the thermostat and water pump operate correctly.

Regular cooling system checks and maintenance are essential for engine longevity and performance.

- Check coolant levels and top off if needed

- Flush and replace coolant periodically

- Inspect hoses and clamps for leaks or cracks

- Clean radiator to prevent debris buildup

- Test thermostat and water pump for proper function

Optimize Oil Change Intervals for Longevity

To maximize your truck’s engine lifespan, optimizing oil change intervals is essential. Regularly changing your oil prevents the build-up of soot, acids, and fuel contaminants that accelerate wear. Stick to the manufacturer’s recommended interval, usually around 5,000 miles, especially if you’re using high-quality synthetic oil. Extending oil changes beyond this can lead to degraded oil film, increased friction, and premature engine damage. High-mileage engines benefit from more frequent oil changes, as they tend to produce more contaminants. Use oils with advanced additive packages for better cleaning and wear protection. Keep an eye on your driving conditions—stop-and-go city driving or heavy loads may require more frequent changes. Consistent oil maintenance guarantees your engine stays protected and performs reliably over many miles.

Keep Engine Components Clean and Free of Contaminants

Keeping your truck’s engine components clean is essential for ensuring long-term durability. Dirt, grime, and sludge can clog passages, reduce heat dissipation, and accelerate wear. Regularly inspecting and cleaning crucial parts helps prevent buildup that can cause overheating or component failure. Use proper cleaning methods to avoid damaging sensitive parts and always follow manufacturer guidelines.

Regular cleaning of engine components prevents buildup and extends engine life.

Consider these tips:

- Check and clean air filters to prevent dust from entering the engine.

- Use degreasers on the engine block to remove oil and grime.

- Flush cooling systems to eliminate mineral deposits.

- Keep fuel injectors and throttle bodies free of carbon buildup.

- Maintain a clean battery and terminal connections to prevent electrical issues.

Staying vigilant about cleanliness supports efficient engine operation and extends its lifespan.

Manage Engine Load and Operating Conditions

Managing engine load and operating conditions is essential for extending your truck’s lifespan. You should avoid excessive towing, heavy loads, and aggressive driving, which put unnecessary strain on the engine. Keep RPMs within recommended ranges; high revs generate more heat and accelerate wear. When driving, aim for steady speeds and smooth acceleration to reduce stress on engine components. Avoid sudden stops and starts that cause thermal and mechanical shocks. Proper warm-up and cool-down routines help prevent thermal fatigue. Additionally, monitor your engine’s temperature gauges and be attentive to abnormal noises or vibrations. By managing load and operating conditions carefully, you minimize internal strain, prevent premature wear, and maximize your engine’s chances of reaching 300,000 miles.

Understand Real-World Factors Influencing Engine Longevity

Real-world factors like driving environment, maintenance consistency, and driver habits heavily influence how long your engine lasts. These variables can accelerate wear or extend engine life markedly. For example, harsh conditions or irregular maintenance can cause premature failures, while careful driving and timely service promote durability. To better understand, consider these factors:

- Driving mostly in stop-and-go city traffic versus steady highway cruising

- Exposure to extreme temperatures or dusty environments

- Consistent adherence to maintenance schedules

- Gentle driving habits versus aggressive acceleration and high RPMs

- Regular inspections and timely repairs of wear components

Frequently Asked Questions

Can Synthetic Oils Significantly Extend Engine Lifespan Beyond 300,000 Miles?

Synthetic oils can markedly extend your engine’s lifespan beyond 300,000 miles. They contain advanced anti-wear additives that reduce friction and internal wear, helping your engine perform smoothly over time. Plus, synthetic oils resist breakdown at high temperatures, keeping your engine cleaner and well-lubricated longer between changes. By choosing high-quality synthetic oils and sticking to recommended oil change intervals, you give your engine a better chance to reach those high-mileage milestones.

How Do Driving Habits Impact Long-Term Engine Durability?

Think of your driving habits as the heartbeat of your engine’s longevity. When you drive smoothly, avoid rapid acceleration, and steer clear of high RPMs, you’re kind to your engine’s soul. Consistent, moderate speeds diminish thermal stress, and proper warm-up and cool-down routines act as a gentle lullaby for your engine. By treating your truck with care, you ensure its long-lasting rhythm beyond 300,000 miles.

What Are the Signs of Impending Component Wear Before Failure Occurs?

You’ll notice signs like unusual noises—knocking, squealing, or grinding—that indicate component wear. Watch for increased vibrations, leaks, or a drop in performance, such as loss of power or rough idling. Overheating or warning lights on your dashboard also signal impending issues. Regular inspections help catch these early, so you can replace worn parts like belts, bearings, or hoses before they cause engine failure.

Is It Better to Rebuild or Replace Engines After High Mileage?

You should consider rebuilding your engine if it’s showing signs of wear but still runs smoothly; it’s like giving it a new heartbeat. Rebuilding restores key components, extends its life, and saves money compared to a full replacement. However, if the engine’s heavily damaged or inefficient, replacing it with a newer, more reliable unit might be better. Trust your mechanic’s advice, but prioritize cost, condition, and long-term durability.

How Does Engine Design Influence Potential for Reaching 300,000 Miles?

Your engine design greatly influences your chances of hitting 300,000 miles. Simpler, robust designs with fewer complex parts tend to last longer because they’re easier to maintain and less prone to failure. Engines built with high-quality materials and proven durability, like certain Toyota or Chrysler models, also have a better shot. Prioritize engines known for longevity, and combine that with proper maintenance, for the best chance at reaching high mileage.

Conclusion

By following these tips, you can help your truck engine reach an impressive 300,000 miles or more. Did you know that regular maintenance can extend engine life by up to 50%? Staying proactive and attentive to your engine’s needs isn’t just smart—it could save you thousands on repairs. Keep your driving smooth, stick to maintenance schedules, and your truck will thank you for many reliable miles ahead.