Bulletproofing your diesel truck engine means upgrading key parts to boost its reliability and durability for heavy-duty use. This includes replacing components like the oil cooler, EGR cooler, head studs, and water pump with stronger, more reliable versions. These modifications help prevent common failures like overheating, leaks, and gasket blowouts. If you want to learn more about how these upgrades work and what they can do for your truck, keep exploring this topic.

Key Takeaways

- Bulletproofing a diesel engine involves upgrading key components to improve durability and reliability.

- It targets common failure points like gaskets, cooling systems, and fuel injectors.

- The process includes replacing parts such as head studs, oil coolers, and EGR coolers with stronger, aftermarket versions.

- It aims to prevent issues like overheating, leaks, and gasket failures, especially in heavy-duty use.

- Only genuine BulletProof Diesel parts and professional installation ensure the effectiveness of the modifications.

Upgraded Stand Pipe & Dummy Plug Replacement Kit for 2004.5-2010 Ford 6.0L Powerstroke F250/F350/F450/F550 | 6E7Z-9A332-B | Fuel Supply Tube – Xotic Performance™ SP100

Heavy-Duty Build & Precise Fit: High-pressure oil stand pipes and dummy plugs CNC-machined from premium heat-treated steel for…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Understanding the Concept of Bulletproofing

Understanding the concept of bulletproofing begins with recognizing that it’s about modifying your diesel engine to be more reliable and durable. You’re upgrading key components to prevent common failures and extend your engine’s lifespan. The term comes from BulletProof Diesel, which developed specific parts for Ford Power Stroke engines, but the idea applies broadly. Bulletproofing isn’t about making your truck bullet-resistant; it’s about addressing weak points prone to failure. By replacing parts like the oil cooler, EGR cooler, head studs, water pump, and FICM, you reduce risks of overheating, leaks, and gasket failures. These improvements help your engine run cooler, more efficiently, and withstand heavy-duty use. Additionally, using high-quality, engine-specific parts can further enhance durability and performance. Ultimately, bulletproofing aims to boost reliability, minimize costly repairs, and keep your truck running smoothly for years.

ARP 250-4202 Stud Kit

Black oxide finish

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

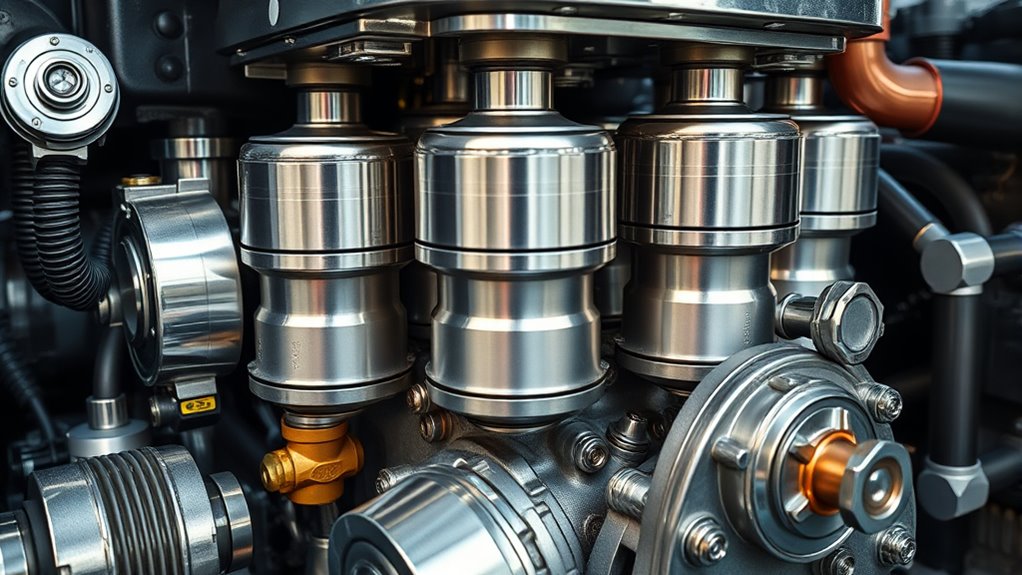

Key Components Targeted in the Process

When bulletproofing your diesel engine, focus shifts to specific components that are most prone to failure. The oil cooler is a top target; replacing the factory stacked plate design prevents clogging and overheating issues. The EGR cooler is upgraded to avoid coolant leaks and exhaust contamination, which can harm engine performance. Head studs are replaced with stronger bolts to prevent head gasket failure under pressure. The water pump, often with a plastic impeller, is upgraded to ensure reliable coolant flow. Lastly, the Fuel Injection Control Module (FICM) is upgraded to maintain proper injector voltage, reducing misfires and improving fuel efficiency. These targeted upgrades address common weak points, substantially enhancing engine durability and reliability over time. Implementing these modifications also contributes to a more streamlined maintenance process, making future repairs easier and more cost-effective.

APDTY 015373 EGR Cooler Kit With Gaskets (Upgraded Stainless Straight Tube Design)

Upgraded design prevents the common clogging and overheating of the original turbulator design

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Specific Ford Power Stroke Models and Their Upgrades

The most common Ford Power Stroke models that benefit from bulletproofing are the 6.0L, 6.4L, and 6.7L engines, each with unique characteristics and upgrade needs. The 6.0L, produced from 2003 to 2007, is the most frequently upgraded due to its known reliability issues, often needing head studs, EGR cooler, and oil cooler replacements. The 6.4L, made from 2008 to 2010, benefits from similar upgrades, especially on the oil cooler and fuel system. The 6.7L, introduced in 2011, is more robust but still can be bulletproofed, mainly through upgraded head studs and cooling components. These models respond well to modifications, notably improving durability, especially for heavy-duty towing and high-mileage applications. Using genuine BulletProof Diesel parts ensures compatibility and effectiveness. Additionally, proper powertrain protection can significantly extend engine life and performance under demanding conditions.

904-225 Engine Oil Cooler Replacement for F250 F350 F450 F550 7.3L # 1C3Z6C610BA 1815904C2 F4TZ6A636A 1C3Z6A642AA 1C3Z6K649BA

🔧 Symptoms of defective or defective oil cooler: coolant in oil; Oil in the cooling system; Oil cooler…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

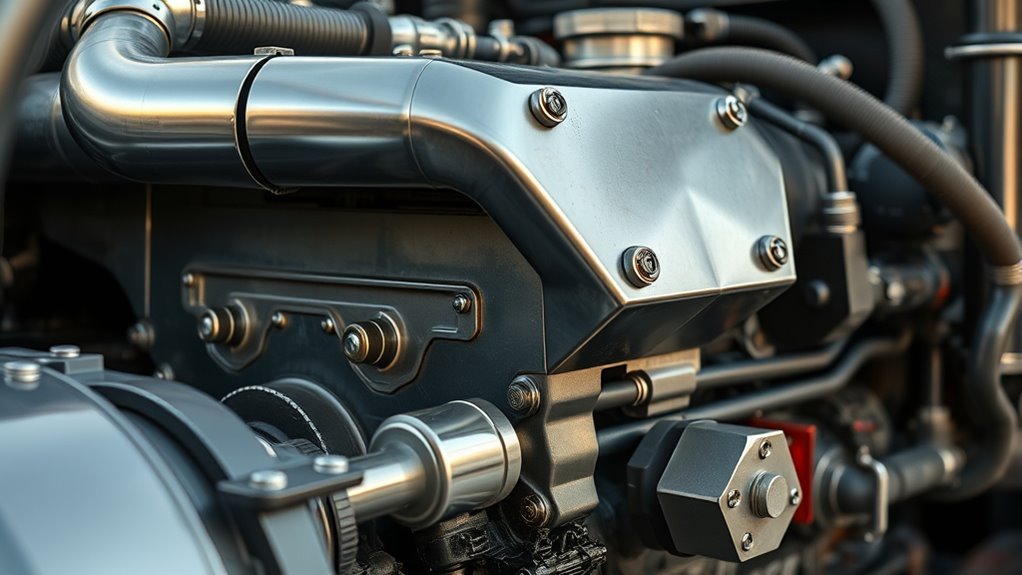

The Bulletproofing Procedure and Requirements

Bulletproofing a diesel truck engine involves a specific process that targets its main failure points to improve reliability and longevity. You need to replace or upgrade key components to guarantee long-term performance. First, you must address at least four of the five critical failure points, such as the oil cooler, EGR cooler, head studs, water pump, or FICM. Second, only genuine BulletProof Diesel parts qualify for an official “bulletproofed” status, ensuring top-quality upgrades. Third, the procedure often includes additional steps like installing upgraded head gaskets or coolant filtration systems. Finally, it’s essential to have a professional perform the work, as precision and proper installation are crucial to maximize benefits and avoid future issues. Proper hydraulic system adjustments are also important to optimize engine performance and durability.

Benefits, Limitations, and Considerations

By investing in bulletproofing, you can markedly improve your diesel engine’s reliability and lifespan, especially under heavy use or towing conditions. It reduces the risk of catastrophic failures, keeps the engine cooler, and extends its overall durability. You’ll notice better performance and fewer breakdowns, saving you money on repairs over time. Additionally, Free Floating techniques can help improve the engine’s efficiency by reducing unnecessary strain and wear. However, bulletproofing isn’t cheap; it can cost several thousand dollars depending on parts and labor. Not all engines can be fully bulletproofed, and some upgrades might void your warranty. Keep in mind that while it greatly enhances reliability, it doesn’t guarantee failure-proof operation. Consider your driving needs and budget carefully before proceeding, and weigh the long-term benefits against the upfront costs.

Frequently Asked Questions

How Long Does a Typical Bulletproofing Upgrade Take?

A typical bulletproofing upgrade takes about one to three days, depending on your truck’s specific model and the extent of the upgrades. You’ll need time for parts removal, installation, and testing to make certain everything runs smoothly. If you’re doing it yourself, expect more time. Professional shops usually complete the job faster, but it still requires a solid day or two to ensure quality and proper upgrades.

Are There Any Risks Involved During the Bulletproofing Process?

During the bulletproofing process, you face some risks like potential engine damage from improper installation or handling, which can lead to leaks or failures. There’s also a chance of voiding your warranty if parts aren’t OEM or installed incorrectly. Additionally, working on the engine inexperience may cause mistakes. To mitigate these risks, hire experienced technicians and ensure they use genuine BulletProof Diesel parts and proper procedures.

Can I Perform Bulletproofing Myself or Should I Hire a Professional?

Like a skilled surgeon tending to a crucial organ, you can attempt to bulletproof your diesel truck if you have mechanical expertise and the right tools. However, this delicate work requires precise installation of parts like head studs and coolant systems. If you’re unsure or lack experience, it’s best to hire a professional. They ensure the job’s done correctly, safeguarding your engine’s longevity and avoiding costly mistakes.

How Often Should Bulletproofed Components Be Inspected or Replaced?

You should inspect bulletproofed components every 10,000 to 15,000 miles or at least once a year, depending on your driving conditions. Regular checks help catch wear or issues early, preventing costly failures. Replace parts like head studs, water pumps, or EGR coolers if you notice leaks, cracks, or performance drops. Staying proactive guarantees your engine stays reliable and extends its lifespan, especially under heavy-duty use.

Does Bulletproofing Affect the Vehicle’s Resale Value?

You’ll find that bulletproofing can act like armor for your truck, boosting its resale value. Buyers see it as a sign you’ve invested in durability and reliability, making your vehicle more attractive and trustworthy. While it might add a premium, it also signals that your truck’s been meticulously maintained. Just keep in mind, overly modified trucks may appeal to a niche market, so weigh the benefits before selling.

Conclusion

Think of bulletproofing your diesel engine like armor-plating a fortress—you’re reinforcing the weakest spots to withstand anything. I once saw a truck that survived a rough Idaho winter thanks to these upgrades, proving their value. Just like adding sturdy walls keeps out invaders, bulletproofing shields your engine from damage and costly repairs. But remember, no fortress is invincible; regular maintenance and smart upgrades keep your truck running strong mile after mile.